Due to its versatility, durability, and cost-effectiveness steel is one of the most widely used materials to diverse applications across construction, manufacturing, and infrastructure. However, its susceptibility to rust poses a significant limitation on its utility.

Impact of the weather conditions

The deterioration of steel is heavily influenced by weather conditions. Why? Iron, which is a key component of steel alloys, oxidizes when exposed to air and humidity. Consequently, surfaces with high porosity are particularly prone to rust, making sharp edges and corners of steel elements especially vulnerable to corrosion. How to enhance its resistance to environmental factors?

The following example illustrates the influence of sharp edges on steel corrosion.

Corrosion of steel construction

Ongoing investments obviously are intended to serve us for as long as possible. Damage resulting from corrosion jeopardizes the properties of steel structures. Thus, ensuring proper corrosion protection is a crucial. Currently, there are two most common methods for preventing rust:

- Application of zinc coating – steel galvanization is the process of creating a zinc coating over the surface of the metal.

- Application of paint coating – painting forms a coating barrier to moisture (which also beautifies metal structures).

Both approaches aim to ensure the reliable performance of steel structures (for a specified period of time). While it is quite obvious that investing in corrosion protection is essential, it is worth noting that its cost-effectiveness depends on proper surface preparation.

How can beveling be your secret weapon against rust?

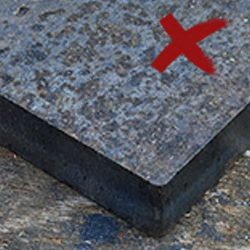

Surfaces with high porosity, i.e. sharp edges and corners of steel elements are especially vulnerable to corrosion. The larger the bonding surface for paint and coatings, the lower the risk of peeling and corrosion.

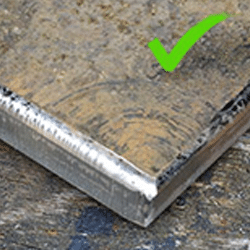

Definitely, well-covered surface is key to preventing rust effectively. The most robust adhesion of the protective layer occurs when the edges of the steel are rounded. To achieve it, the edges of the steel may be rounded with a special type of beveling process. By producing a perfect radius on material edges, PROMOTECH beveling machines boost protection against rust, extending the lifespan of steel.

In most applications, beveling involves removing a specific volume of metal at a required angle along an edge prior to welding. Rounding, on the other hand, means removing metal from a sharp edge to create uniform radius. This results in a larger bonding surface for paints and coatings, reducing the risk of peeling and corrosion.

Choosing right beveling machine

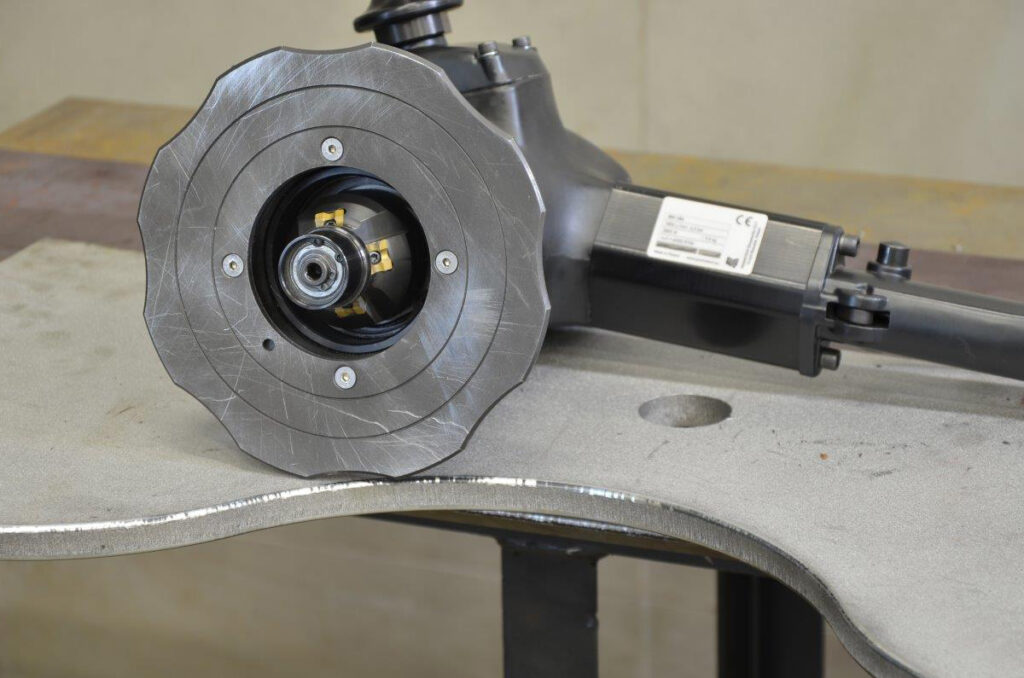

Proper beveling machines may play a key role in safeguarding steel from rust. In today’s market, there is a wide array of chamfering machines that eliminate the need for flame cutting and grinding procedures. These machines come equipped with numerous specific features and options. They allow for various machining operations on plates, tubes, or pipes such as beveling, facing-off, “J” prepping, counter boring or cladding.

Not every beveller, however, is suitable for this task. What we need is a beveling machine specifically designed to produce a consistent, uniform radius, regardless of whether an R2, R3, R4 or R5 is required. Only then do they meet requirements for corrosion protection and extending the longevity of steel structures.

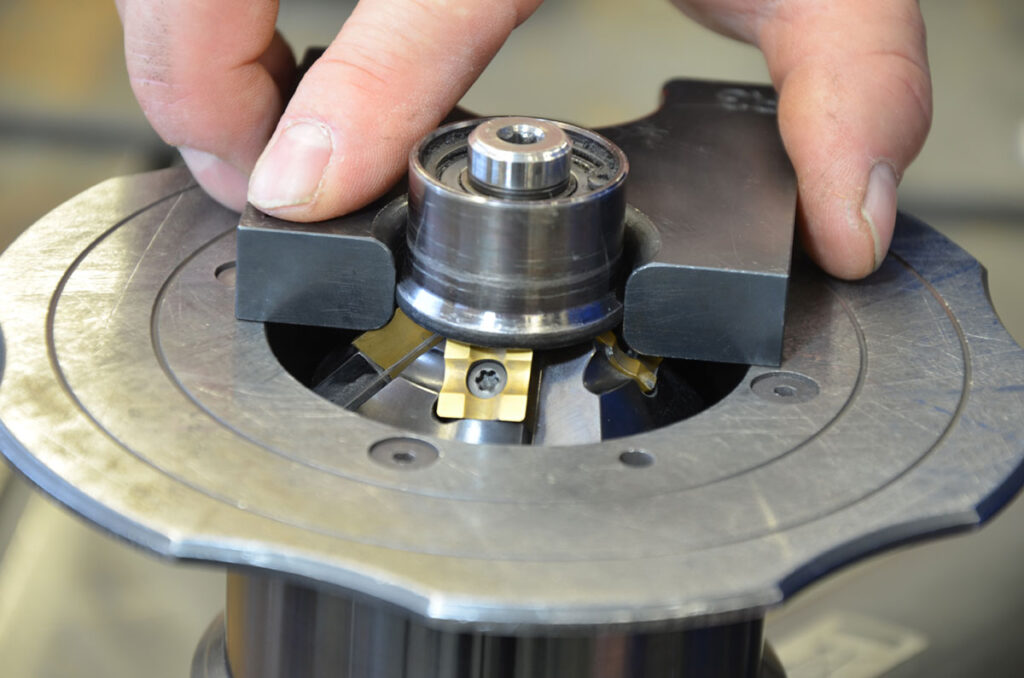

It’s worth highlighting beveller machines which are equipped with a practical single 45-degree 4 tip cutting head, capable of handling both V bevels and rounding, i.e. bevellers such as BM-7, BM-18 and BM18A.

Depending on inserts in use, these machines can either do the bevel of the welding seam preparation or create the required size of smooth and consistent rounding. All that in just one pass, saving time and money over conventional grinding methods. By enhancing adhesion, they effectively prevent rust, ensuring your steel endures the test of time.

Operators greatly value also the compact design and lightweight nature of these PROMOTECH beveling machines, which make them well-suited for use in space-restricted areas.

The importance of radius edge bevel

Before applying the coating, the surface of the alloy must comply to technical standards. Current directives such as EN 1090 and EN-ISO 12944 Part 2 specify the necessity of applying a soft or radius edge to all steel sections before painting. This prevents rust build up on sharp edges. The covered area must be smooth and with no sharp ends – as it significantly minimizes corrosion of steel.

Failing to provide adequate protection for steel plates, one can observe paint flaking over time, resulting in plate corrosion, especially in the area of sharp edges. On the other hand, creating a perfect radius on material edges prior to painting holds crucial implications for the durability of the material cover.

In summary, protective coatings are essential but only when one ensures a uniform radius on material edges before their application. The rust protection process starts with proper preparation of the bonding surface. Opting for the handy, reliable beveler that creates perfect rounding eliminates the need for time-consuming finishing processes. For optimal results, choose your machines wisely.

Check our bevellers capable of handling both V bevels and rounding:

- PROMOTECH BM-7 compact pipe and plate beveller >>

- PROMOTECH BM-18 multitask pipe and plate beveller >>

- PROMOTECH BM-18A pneumatic plate beveller>>