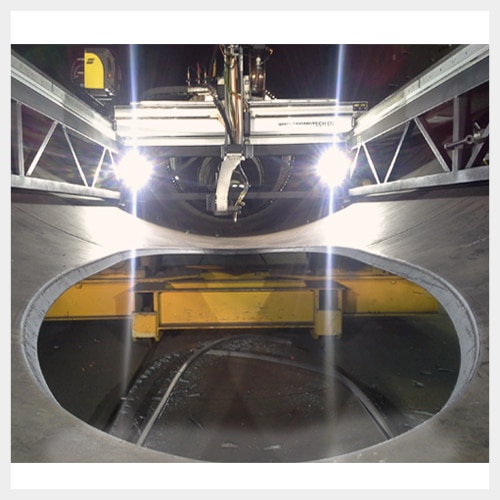

MCM | 5-axis portable CNC cutting & welding machines

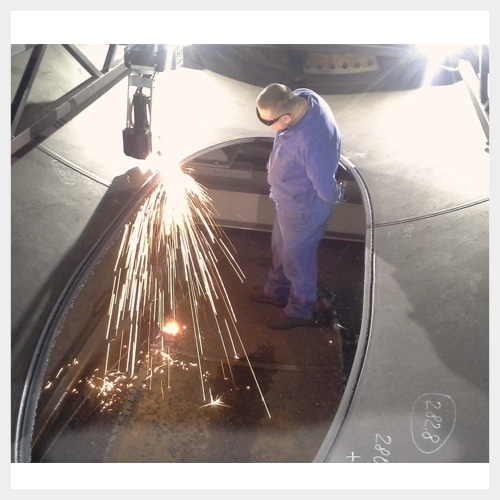

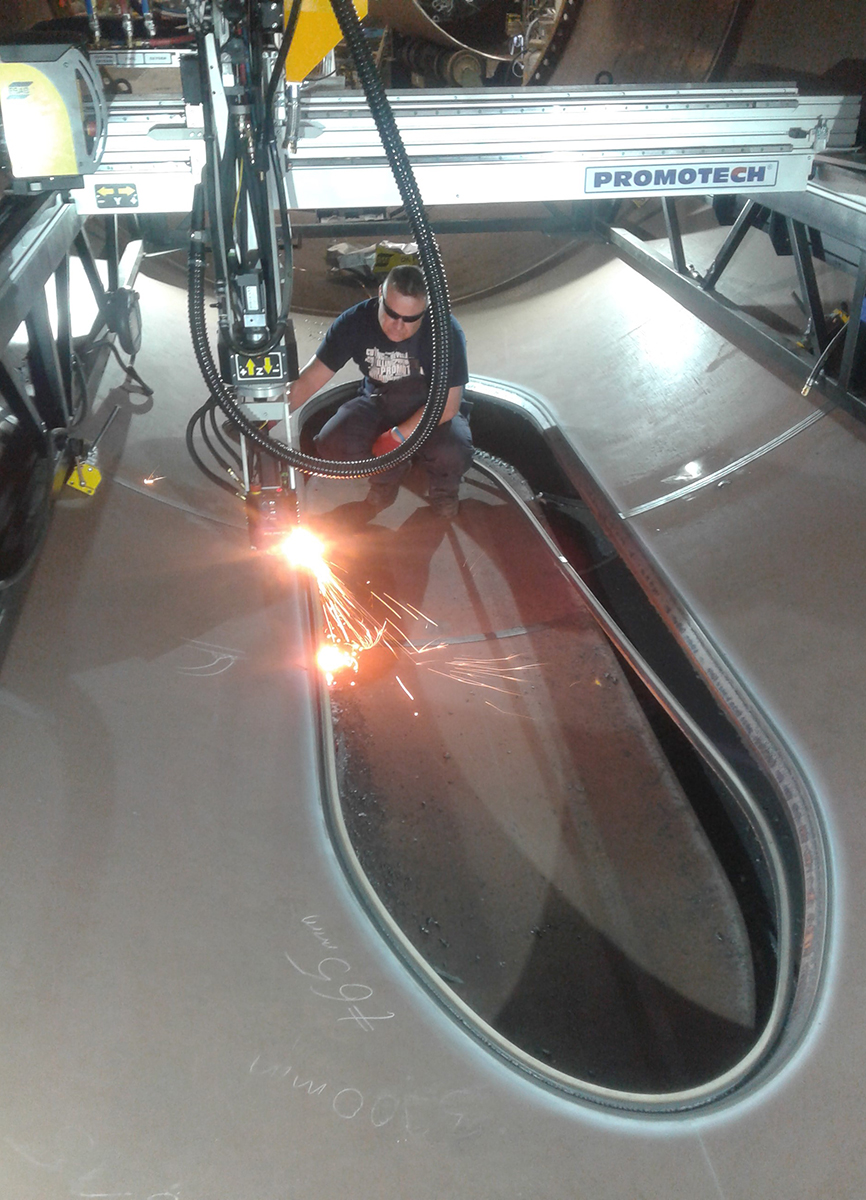

MCM machines are true portable CNC scanning, cutting, beveling, and welding machines that eliminate the biggest bottleneck in steel wind tower production On & Offshore! MCM 3D Oxy-fuel CNC 3D cutting & beveling head ensures top-quality welding preparation each time! MCM SAW ACDC welding head/processes that increase deposition rate, and boost productivity will significantly reduce the largest component of welding costs – labor and overhead!

- Short setup time and easy handling

- Each workpiece (e.g. door frame) is scanned to automatically generate individual CNC cutting/beveling and CNC welding path

- Top-quality weld preps

- Precise root gap 1-3 mm and welding defect rate less than 1%

- No grinding

- One-man operation with online support connection

- Excellent Return On Investment (ROI)!