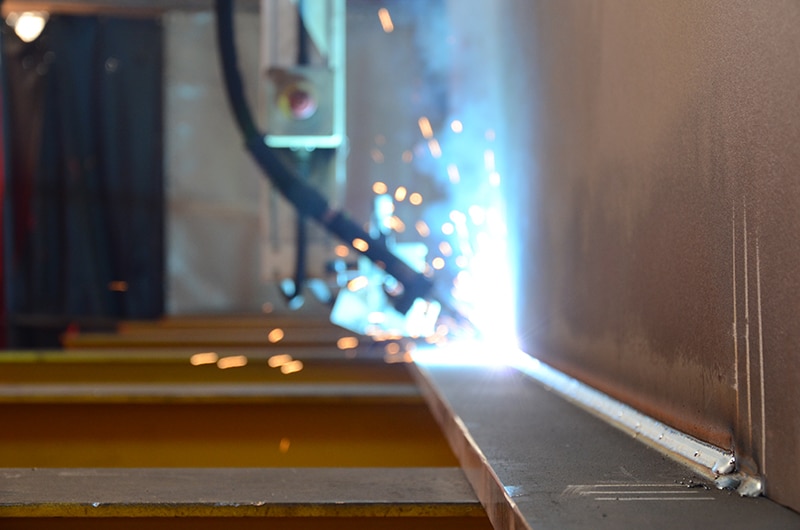

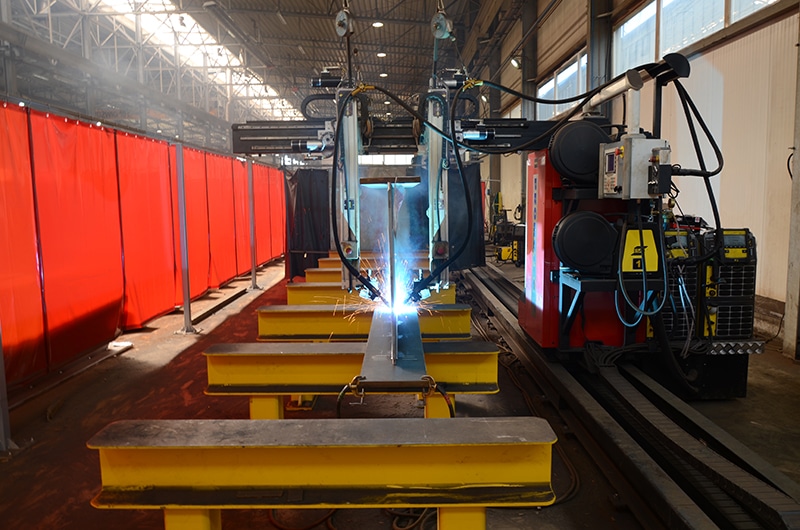

Half gantry welding system WA 1000 / WA 1500

Automatic longitudinal welding with joint tracking system for structural beam types H, I, T, L, HKS, HSQ and tapered. It includes a mechanical automated seam tracking system and is suitable for SAW / GMAW welding process. WA 1000 / WA 1500 allows programming the welding sequence and welding parameters in an automatic cycle.

- Automatic fillet and butt welding with joint tracking

- Multipass welding

- One-man operation

- Reduction of costly over-welding and decrease of filler metal usage

- User-friendly interface – multiple languages

- Accepts most welding MIG-MAG power sources