ABM-50 DD Vario: Excellent results, minimal effort

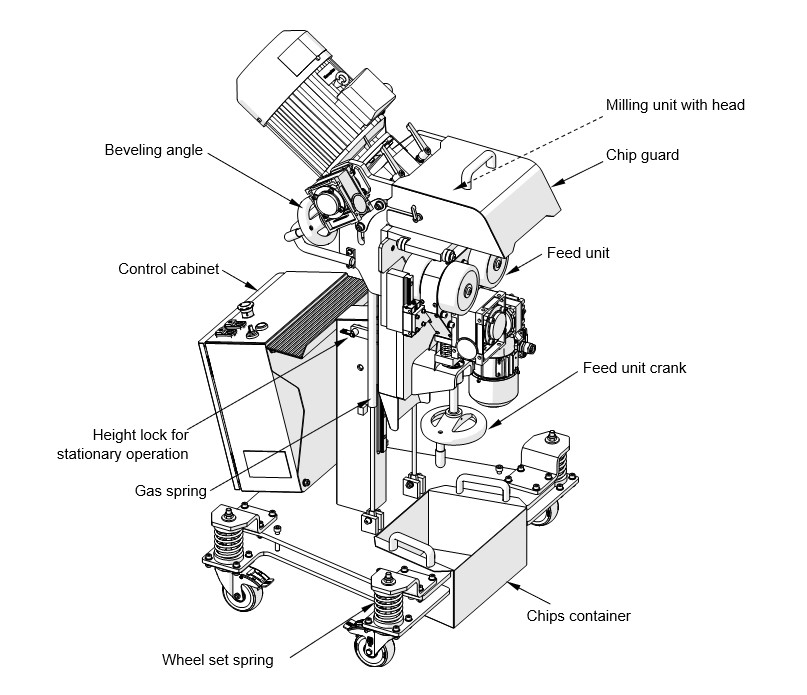

ABM-50 DD Vario is a self-propelled, heavy-duty bevelling machine engineered to deliver high-quality bevels up to 50 mm wide, without thermal distortion or a heat-affected zone (HAZ).

Whether you’re preparing structural steel for large construction projects or fine-tuning weld prep in the workshop, the ABM-50 DD Vario delivers precise, efficient, and repeatable results.

Smart Tool for Demanding Bevelling Applications

Engineered for precise edge preparation on thick plate materials from 8 mm to 80 mm, ABM-50 DD Vario is a great support for anyone working with carbon steel, stainless steel, duplex, Hardox, and other challenging materials.

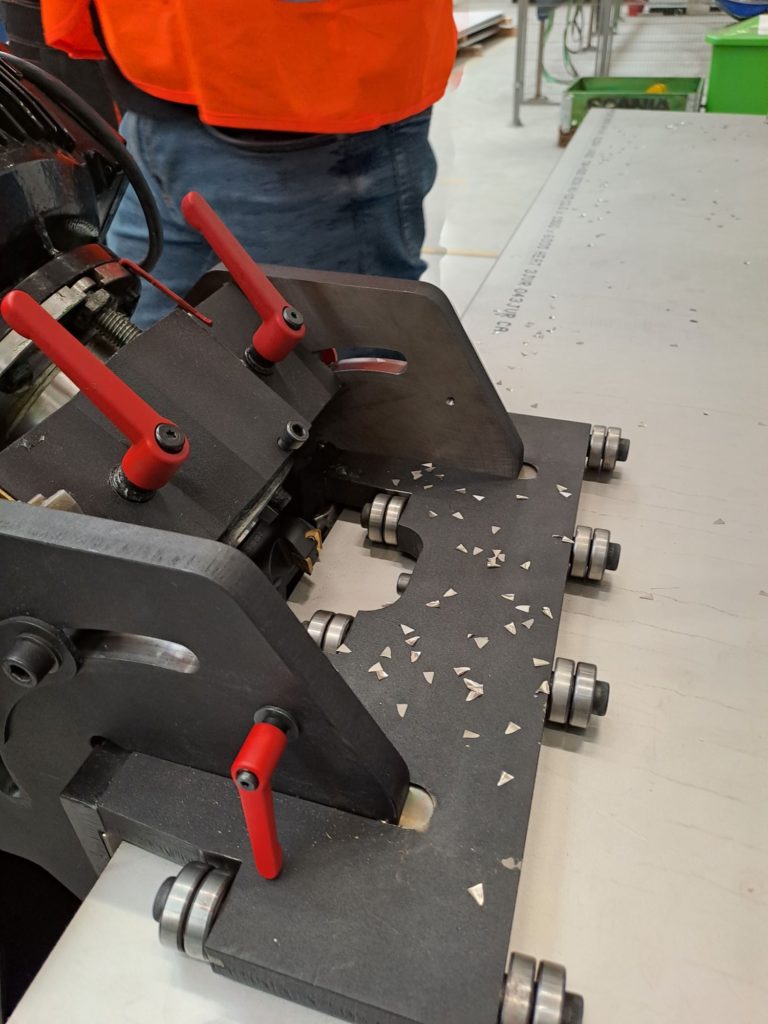

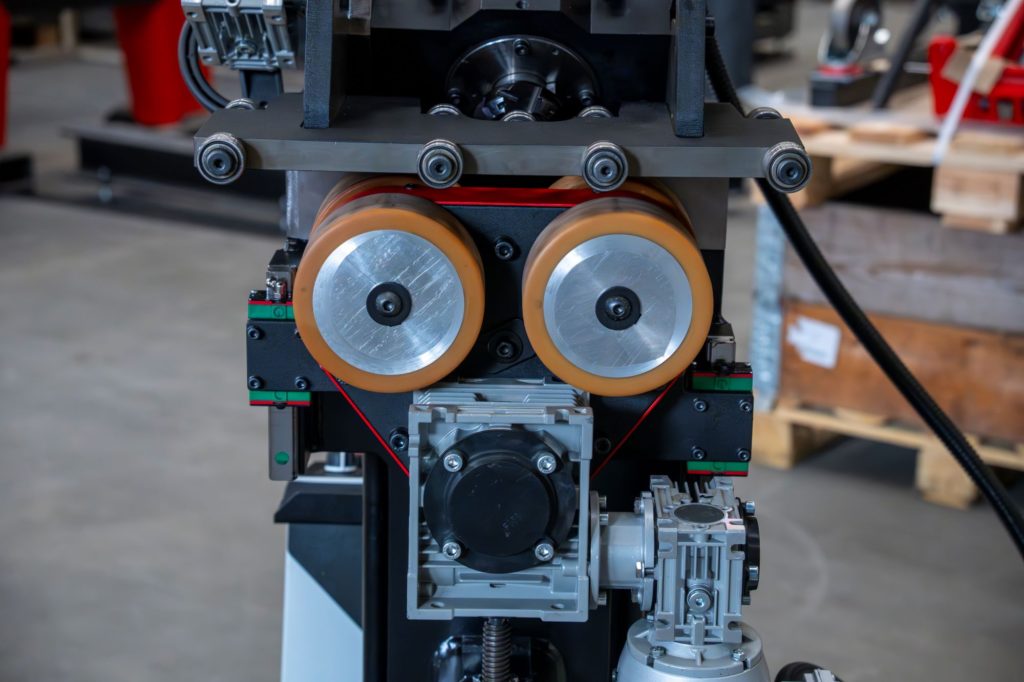

Auto-feed drive system allows ABM-50 DD Vario to travel along the workpiece at speeds of up to 1.2 m/min, reducing operator effort and improving consistency over long plate lengths. In addition, the spring-loaded castors on the carriage compensate for surface irregularities or lack of parallel alignment between the workpiece and the floor, ensuring smooth, stable operation throughout the bevelling process.

Clean, Cold Bevels

Unlike thermal cutting methods, the ABM-50 DD Vario employs a high-performance rotary milling head fitted with indexable cutting inserts to produce clean, cold-formed bevels. This mechanical approach eliminates the risk of heat-affected zones (HAZ), preserving the structural integrity and mechanical properties of the base material.

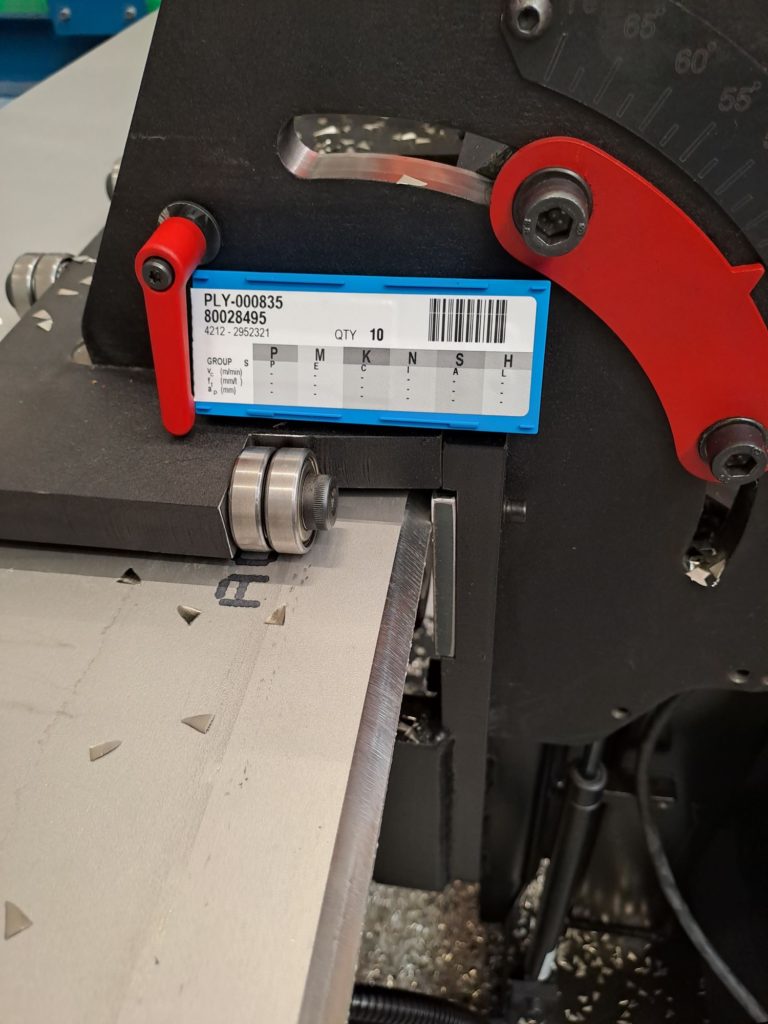

Five 4-sided indexable cutting inserts can be rotated or replaced to maximize tool life and minimize downtime. A wide selection of insert types is available—each tailored for specific material classes—ensuring stable, high-quality cutting performance and a precise surface finish across a wide range of steel materials.

Adjustable Feed and Spindle Speed

Thanks to the variable spindle speed 500-1450 rpm and adjustable feed rate, users can easily optimize cutting parameters to suit various steel grades. However, for users working exclusively with carbon steel, a simplified variant with a fixed spindle speed — the ABM-50 DD — is also available.

Spindle rotational speed (without load) for ABM-50 DD is fixed at 1450 rpm (50 Hz), 1750 rpm (60 Hz). It is a cost-effective alternative when variable cutting parameters are not required.

Continuous bevel angle adjustment

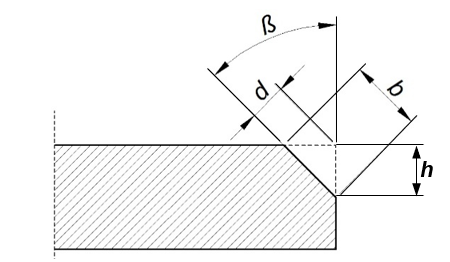

ABM-50 DD Vario is not limited to one fixed angle. Instead, you can adjust your bevel angle from 15° to 70°. The bevel geometry achieved depends on the combination of bevel angle (β), bevel depth (d), and bevel height (h).

| β | 15° | 30° | 45° | 60° | 70° |

|---|---|---|---|---|---|

| b | 41.8 mm (1-41/64″) |

46.2 mm (1-13/16″) |

50.2 mm (1-31/32″) |

46 mm (1-51/64″) |

42.9 mm (1-11/16″) |

| h | 40.4 mm (1-19/32″) |

40.2 mm (1-37/64″) |

35.5 mm (1-25/64″) |

23.1 mm (29/32″) |

14.7 mm (37/64″) |

| d | 15 mm (19/32″) |

21 mm (53/64″) |

25 mm (63/64″) |

21 mm (53/64″) |

17 mm (43/64″) |

LED overload monitoring system

An integrated LED load monitoring system provides real-time feedback using green, yellow, and red indicators to help prevent motor overloading and protect the milling system under varying load conditions.

Conclusion

The ABM-50 DD Vario is a robust, adaptable bevelling solution that handles with confidence even demanding applications. Combining cold milling technology, adjustable operating parameters, and multi-material compatibility, it provides a highly efficient alternative to thermal or manual edge preparation—reducing both processing time and operational costs.

Key performance specifications:

- Self-propelled operation with auto-feed: moves along the plate edge at up to 1.2 m/min Bevel angle range: 15°–70° (continuously adjustable)

- Bevel width: up to 50 mm at 45° (continuously adjustable)

- Plate thickness range: 8–80 mm

- Height adjustment: 840–1040 mm from floor level (for top-edge bevelling)

- LED overload monitoring system

- Milling head equipped with 5 pcs of 4-sided indexable cutting inserts

- Stationary operation for machining small workpieces