Since increasing the total height from 93 to 143 meters can boost the yield by up to 50% (even at low wind locations), it is no wonder that wind towers are getting taller and taller. However, the side effect is that the bottom tower section plate thickness rises even over 65mm in the door frame section. Wind tower entrance door opening has to be then additionally reinforced with an oval steel door frame.

Wind tower door frame installation can be easier and more effective with PROMOTECH MCM machine. Click here to see product website >>

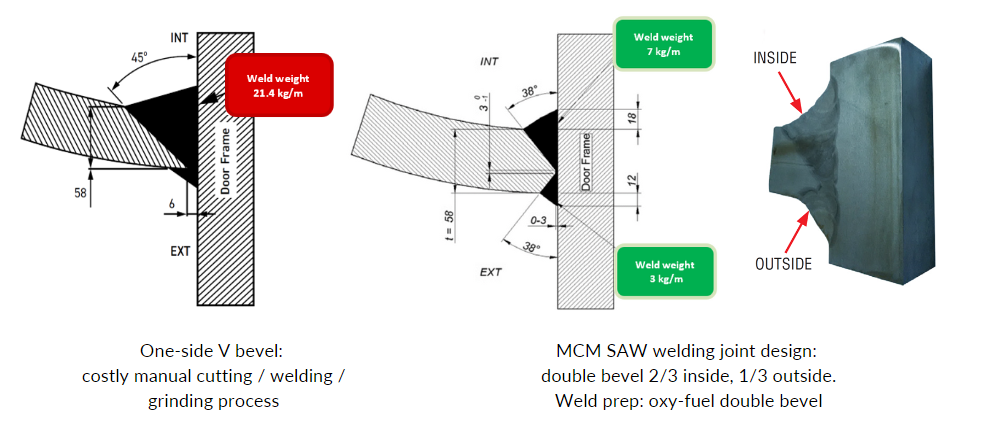

To comply with the design norms, the door frame is made of heavy-duty steel plate 400-500mm deep with thicknesses that ranges from 50mm up to 100mm. To mount such entrance door usually requires at least 100 hours of manual welding. If you add manual cutting/bevelling and welding repairs, the total time can exceed 200 working hours. In practice, this means that costly, manual welding and repair work turn out to be the main bottleneck of such project.

How can one improve it? Either you stay with old technology, lower quality and lower income, or you find the solution to reduce your welding costs instead. Entrance door is an essential part of every wind tower that provides safe access for operators or technicians for maintenance, emergency response, regulatory compliance and facilitating the construction process. But, how to lower the cutting, bevelling and welding costs of door frames ? You can replace manual welding and cutting with PROMOTECH MCM – Manhole Cutting, Bevelling & Welding Machine and benefit from high efficiency and high quality.

Addressing the door frame challenge with PROMOTECH MCM

For over 10 years PROMOTECH has been manufacturing this unique machine that manages to significantly increase the entire efficiency of door frame installation into wind towers. MCM is a 5-axis portable CNC scanning, cutting, bevelling, and welding machine that enables remarkable precision and a major reduction in welding time and reduction welding materials. It offers new efficiency which can redefine your business operations in wind tower manufacturing.

MCM can be up to 6 metres long and 3 metres wide and allows to insert the wind tower door frames up to 1400mm wide and 4500mm high. It is a multitask – cutting/bevelling and welding solution, so all multi-pass work may be done with one machine and one operator and in one set up.

Easy wind tower entrance door frame installation with PROMOTECH MCM

Unlike typical robotics solutions, PROMOTECH MCM system does not require:

- Complex CNC programming

- Highly skilled operators

- Additional CAD/CAM software

- Costly optical seam tracking

- Costly and troublesome automatic flux handling equipment

PROMOTECH MCM’s worldwide premiere took place at Essen Welding Show in 2009 in Germany. Now, with numerous very successful MCM on&offshore applications delivered world-wide, we have accumulated a great deal of experience and expertise. Door frame welding is no challenge to MCM.

How is PROMOTECH MCM better than the manual welding?

For those companies that still hold on to using traditional, time-consuming manual processes, the primary challenge is the time- and money-consuming factor of the door frame process. The curvature of the door frame shape is never 100% identical, so without MCM it is difficult to ensure much required accuracy and repeatability. Then, remember that the typical frame is at least 2-inch thick and thus, obviously, difficult to handle.

Hand-cutting of the door frame exact shape relying only on a simple template obviously lacks precision that only automation can provide. Achieving the essential levels of accuracy and consistency through manual welding alone proves challenging, material-consuming, and requires longer working hours. What is more, it usually relies on a small group of very experienced welders who are more and more scarce year by year.

Improve the process and maximize profits with PROMOTECH MCM: A Return on Investment

On-site manual welding with the use of hand-held torches takes long time and significantly burdens the budget. Depending on the operator’s skills, the tower’s bottom section plate thickness, and the size of the door frame, this process can take 100 hours or more.

PROMOTECH’s cutting-edge MCM machine is engineered to enhance productivity and maximize profits. This is facilitated by the precise and efficient “3-in-1” process. Time reduction can be achieved by the following: laser scanning, top quality oxy fuel cutting & bevelling, precise door frame assembly and finally SAW ACDC welding inside and outside of tower section. All these stages can be operated by one person. Speed control system which stabilizes travel speed enables consistent heat input. This way, weld defects and costly repair work are eliminated.

Total process time at bottom section plate thickness of #60mm for a single operator is 40 working hours. For taller towers with thicker shells, the working hours increase proportionally.

Using two MCM machines and an external platform for the second machine, the wind tower manufacturer may achieve up to 5 bottom sections with door frames per week with plate thickness of #60mm.

It is important to note that:

- No welding face grinding after finished SAW welding is necessary

- Can be accomplished within 5 working days / 3 shifts / 6 operators

- Welding defect rate is usually reduced to less than 1%.

How easily can you produce the tower entrance door with MCM?

PROMOTECH MCM (Manhole Cutting, Bevelling and Welding Machine) is a 5-axis portable CNC cutting/bevelling and welding machine which allows all multi-pass work to be done with one machine, in one set up and by a single operator. As the curvature of the inner wall usually vary slightly in each tower section, the whole process begins with the operator scanning the tower door frame geometry and then, the surface inside of the tower section. Then, the operator is ready to perform cutting and bevelling.

Next, using equipment such as a forklift, the door frame can be placed in the bottom section. At the same time MCM operator needs to change the cutting torch to SAW welding torch. Now multi-pass ACDC around the frame can be performed. After completing inside welding, the section is rotated on the turning rolls 180 degree. Then the MCM can be placed on the top and secured with an external platform. This way the whole external welding task can be completed efficiently, quickly and safely.

Uninterrupted workflow: PROMOTECH MCM installation, training and support services

PROMOTECH dedicated customer support ensures an easy transition to new, more effective MCM methods. Following expert set up and comprehensive training services at end-user’s site, one can confidently integrate the MCM solution into most existing processes of wind tower door frame installations. MCM allows manufacturers to benefit from massive improvement: uninterrupted workflow, high quality, 24/7 efficiency and high quality results.

Our experienced technicians will visit end-user’s site to install the PROMOTECH MCM, conduct the training, sharing their know-how and showing in practice how to do the scanning, cutting and welding with MCM machine.

PROMOTECH MCM comes with worldwide warranty and post-warranty service. To enhance full customer support, all MCM machines come equipped with a built-in network router. This feature enables with the owners clear consent, PROMOTECH’s remote access to the MCM interface, allowing its engineers to perform diagnostics, troubleshooting, and upload software updates when requested. Thus, addressing any concerns promptly, minimizing downtime and maximizing productivity.

On-shore, off-shore and more

Over the years, there has been a growing demand for MCM machines in both on–shore and off–shore applications. No wonder. By replacing manual cutting, grinding and welding with PROMOTECH MCM machine, one can eliminate one of the biggest bottlenecks in wind tower manufacturing – fitting the door frame into the tower’s bottom section. MCM’s precision, repeatability and reliability can lead directly to reduced manufacturing costs.

What is more, PROMOTECH MCM has found applications in other projects involving 100mm thick plates cutting and bevelling.

MCM machines have been successfully used in fabrication of cylindrical or spherical pressure vessels. Also in preparation of different types of openings for cables, water, sonars, ICCP installation or jack up vessels which are used for erecting of off-shore wind towers. Over the years PROMOTECH MCM machine has proven itself on all continents as a reliable, precise and efficient solution.

Today’s dynamic world brings new challenges and the need for constant development of industrial technologies. PROMOTECH MCM will continue to evolve and to address those challenges and support innovative solutions in various industries.

Learn More About the MCM Wind Tower Entrance Door

Are you interested in the PROMOTECH MCM machine and how it can enhance your projects? We’re here to provide you with all the details you need. Fill out the form below to get in touch with us, and we’ll respond promptly.