Why equip rail free welding tractors with tracks?

PROMOTECH offers a wide range of welding and cutting tractors, so that customers can choose between rail free and rail-mounted models to suit their specific application needs.

Benefits of using rail free tractors

Thanks to their compact and lightweight design, rail free welding carriages are engineered for maximum mobility. They are easy to transport and set up in various locations, including inside tanks or other confined spaces. Self-guiding roller arms eliminate the need for track, allowing the units to be quickly positioned and repositioned.

This is very useful in dynamic work environments with frequent job changes and short-term, on-site or field tasks that demand minimal setup time.

36 mm and 120 mm wide flexible tracks

In specific cases, however, rail free tractors can benefit from the additional support provided by optional tracks. One pragmatic reason is that users who already own a rail free tractor would like to use a single machine for a wide variety of short tasks.

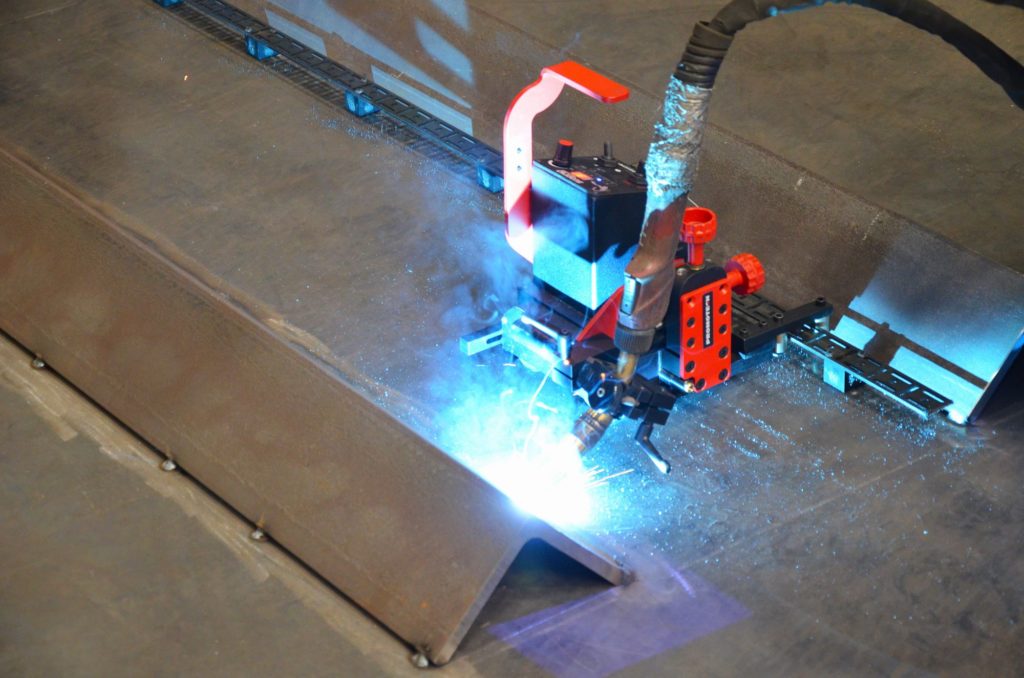

PROMOTECH offers two options dedicated to rail free tractors: 36 mm wide flexible track and 120 mm wide flexible track. While GECKO, GECKO Battery 2, and SCORPIO Battery can be used with both 36 mm wide flexible track and 120 mm wide flexible track, LIZARD is compatible solely with 36 mm wide flexible track.

Expanding welding possibilities

Supporting rail free carriages with tracks broadens their range of applications. This includes working on complex geometries – on curved, concave, and convex surfaces.

When working on curved workpieces such as pipes or tanks, rail free tractors need to be used with tracks. They provide better grip and stability, preventing the tractor from slipping and ensuring precise weld path control.

Non-ferrous or thin-walled materials

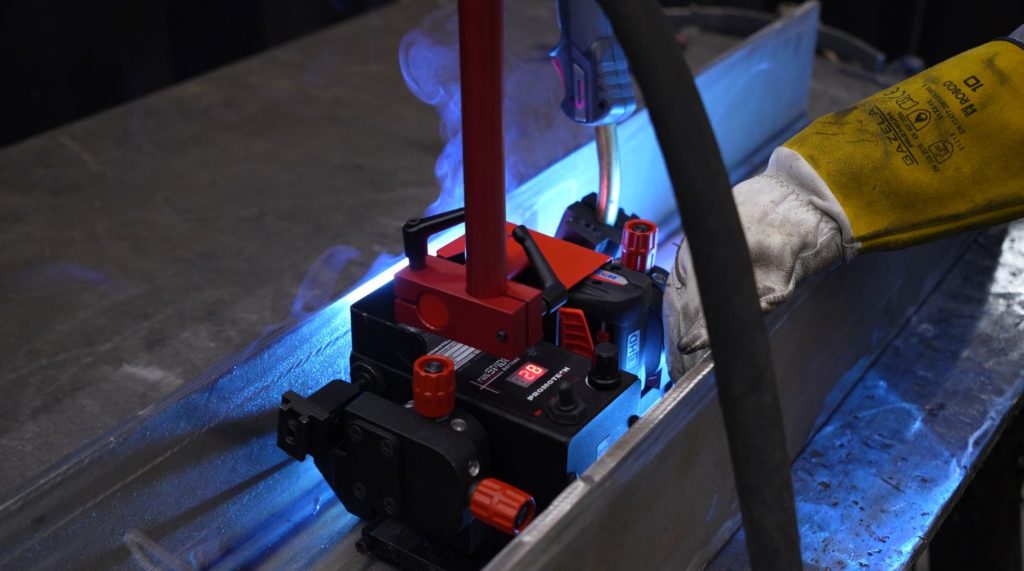

As rail free tractors rely on magnetic traction, they perform best on magnetic, flat, and even surfaces such as structural steel plates or beams. On non-magnetic materials like aluminium or stainless steel, or on thin-walled components, rail free carriages should be used with a vacuum trackway system.

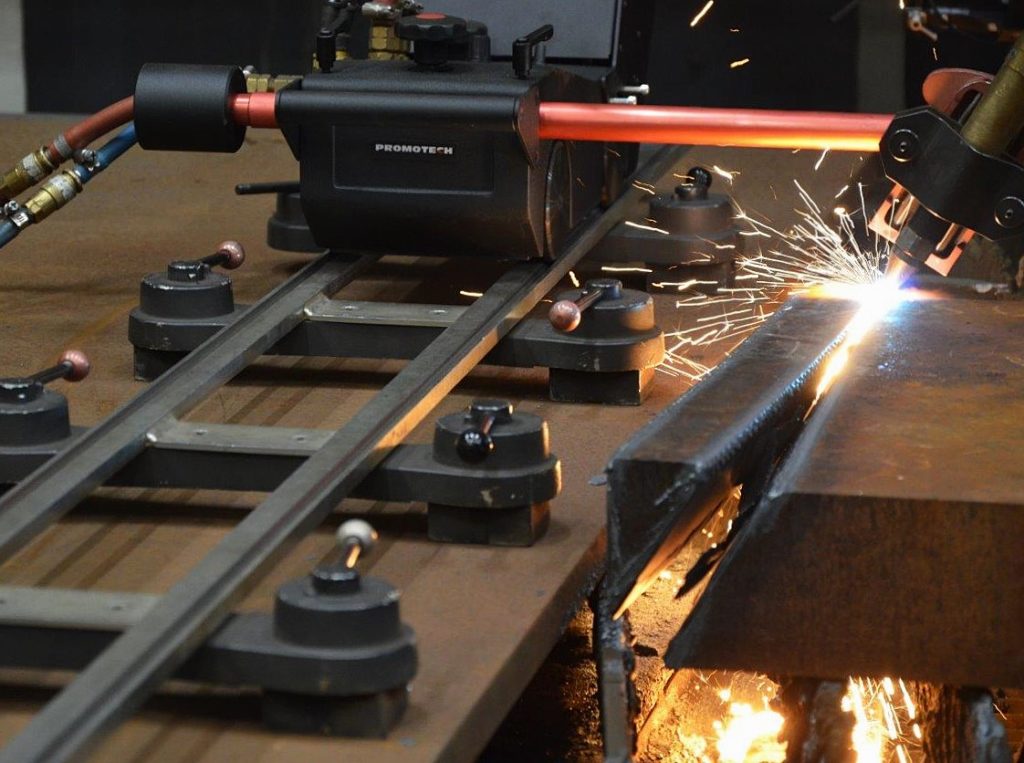

Uneven surface

If the welded structure (e.g. a plate, profile, or pipe) has surface irregularities or joints, these may cause the rail free tractor to bounce or deviate from the intended welding path. In such cases, the use of 36 mm wide flexible track or 120 mm wide flexible track enhances stability and ensures that the tractor maintains its intended path, even over uneven or deformed surfaces — without slipping, bouncing, or changing trajectory.

No Edge to Follow

Using a track becomes very helpful in a situation when there is no fixed reference point or a stable surface to position the tractor on. 36 mm and 120 mm wide flexible tracks provide a guided path for the rail free tractor, ensuring straight and consistent travel, even on large, open, or uneven workpieces. It helps the operator maintain precise torch positioning and welding direction, especially in situations where there’s no natural edge, joint line, or other physical support to follow.

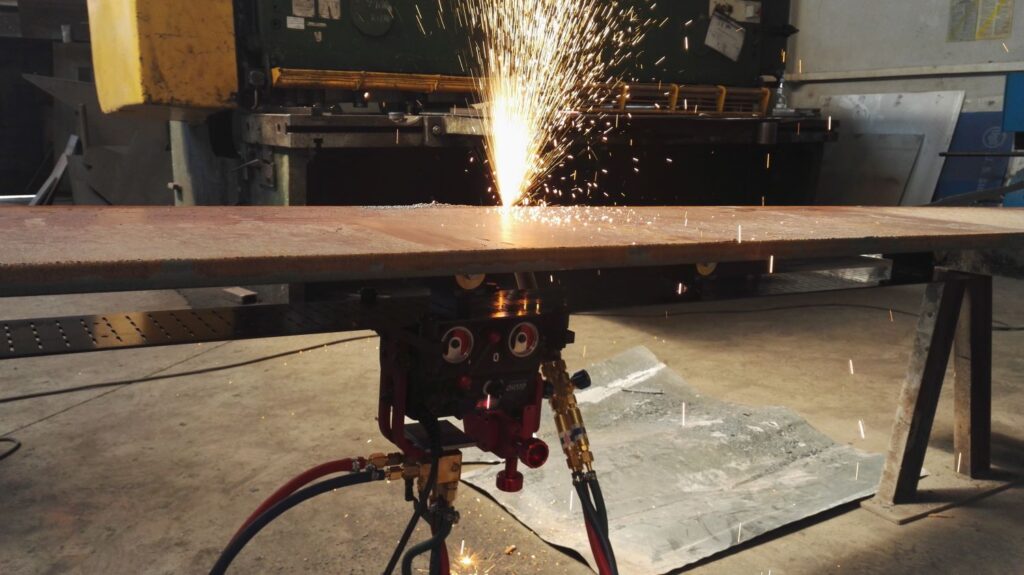

Cutting with PROMOTECH tractors

PROMOTECH’s welding tractors can also be efficiently used for cutting applications – either rail-mounted or rail free. When equipped with a 36 mm or 120 mm wide flexible track, rail free tractors gain a stable travel path that minimizes vibrations and guarantees smooth movement.

In PROMOTECH offer users can also find tractors designed exclusively for cutting operations — the DRAGON series, which includes the DRAGON, DRAGON Battery, DRAGON HS, and DRAGON 42V models. These units move along a dedicated V-track engineered specifically for the series and are equipped with heat-resistant components to withstand the intense heat, sparks, and slag generated during the cutting process.

To sum up, the use of tracks enhances the rail free tractors’ operational versatility. While rail free models offer excellent mobility and quick setup, adding a track provides the extra stability and consistent movement needed when working on curved, uneven, or non-magnetic surfaces — or whenever there is no clear reference edge to follow. In such situations, tracks help maintain accurate torch positioning, prevent slipping, and ensure consistently high-quality welds and cuts.