One Machine. Endless Applications: The Versatility of PROMOTECH GECKO Carriage

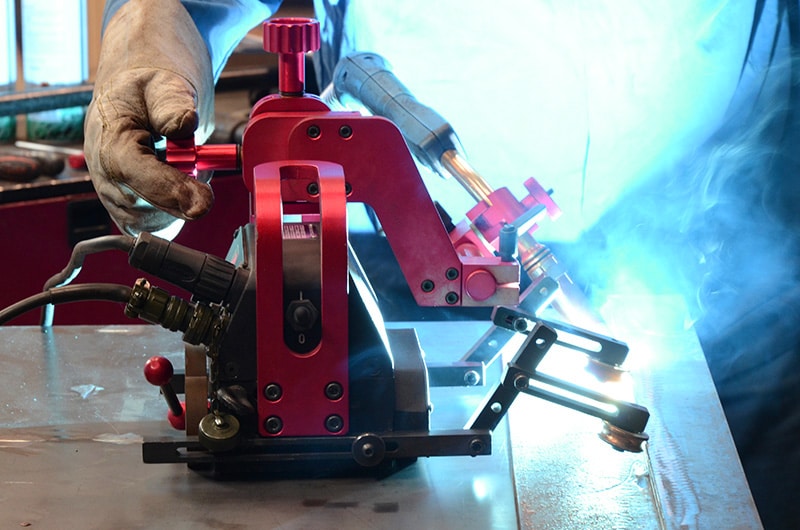

The GECKO is a trackless welding tractor engineered to deliver continuous butt and fillet welds on carbon steel, stainless steel, and aluminium, using MIG/MAG torches. Thanks to numerous accessories, GECKO can be used for a remarkable range of welding applications – a key reason behind its popularity among welders. And at just over 8 kg, this compact, portable tractor can be carried anywhere.

Wide Range of Welding Positions

PA / 1F / 1G – Flat Position

Welding from the top side of the joint, face upward

PB / 2F – Horizontal Fillet Position

Fillet weld applied on a horizontal surface against a vertical one

PC / 2G – Horizontal Groove Position

Butt weld with the axis of the weld horizontal and weld face vertical

PD / 4F – Overhead Fillet Position

Fillet weld performed from below the joint

PE / 4G – Overhead Groove Position

Butt weld performed from underneath the joint

PF / 3G – Vertical Up Groove Position

Butt weld in vertical position, welding upward

Wide Range of Welding Applications

Renowned for its exceptional versatility, the GECKO welding carriage is adaptable to handle a wide range of applications, including out-of-position welding. By minimizing over-welding, it helps save time, reduce filler metal consumption, and improve overall welding efficiency.

Its 4-wheel drive system, combined with powerful magnetic traction, ensures continuous contact with the workpiece. Additionally, the digital speed control system with a built-in feedback loop maintains a stable travel speed, even in vertical, overhead, or out-of-positions welding.

A multifunctional LED display shows both actual and set travel speeds, along with system messages for clear and convenient monitoring.

Users can select arc ignition times of up to 5 seconds at the start and end of the GECKO travel to create a preferred weld fill at both ends.

The carriage features heat-resistant rubber wheels that ensure smooth and stable movement, even in applications where the tractor moves closer to the hot weld seam, during long or multi-pass welds. Thanks to their thermal resistance, silicone wheels maintain their shape and grip under high temperatures, reducing wear, the need for frequent replacements, and minimizing downtime.

When welding in the horizontal position on a preheated plate, use optional stainless steel wheels (KOL-0466-72-00-00-0).

Tracks

Permanent magnet at the carriage bottom ensures proper adhesion to ferromagnetic surfaces and self-guiding roller arms eliminate the need for track. GECKO is well-suited for complex assemblies, such as circumferential and irregular surface applications down to min. radius of 600 mm (while working outside) and 800 mm (while working inside).

Flexible track

Flexible track can be mounted to ferromagnetic work surface with magnetic blocks. It allows guiding the carriage on flat surfaces along a straight line, and on pipes and tanks. A single flexible guide is 1.85 m (6 ft) long. Its minimum curve radius is 1 m (3.3 ft).

Flexible trackway

Using an optional flexible trackway set allows the carriage to move on both ferrous and non-ferrous materials by means of magnetic or vacuum units. A single flexible rail is 1.88 m (6.1 ft) long and its minimum curve radius is 1.25 m (4.1 ft). It can be clamped to flat surfaces, pipes, or tanks.

Vacuum track system

The vacuum track system can be used for clamping flexible trackway at places where magnetic clamping is not possible, including stainless steel and aluminium. When paired with a vacuum pump, the vacuum units ensure secure attachment to non-ferromagnetic surfaces.

At a gauge pressure of –0.7 bar (–10 psig) and standard atmospheric pressure at sea level, the system provides a holding force of up to 1400 N. Please note that this holding force decreases with altitude. To increase the overall clamping strength of the trackway, additional vacuum units can be employed.

Read more about vacuum system >>

Enhanced Functionality Through Optional Accessories

With the addition of optional accessories, the GECKO carriage handles complex geometries and travels along outside edges, lap joints, and templates, and operates reliably on low or perforated walls, as well as on ceilings, pipes, and tanks.

Quick clamping torch holder mechanism allows for MIG/MAG torches with diameters of 16-22 mm (5/8”-7/8”). While screw-driven cross slide ensures precise torch adjustment, using the optional 76 mm cross slide extends the up-down or left-right adjustment range from 0–35 mm (0–1.38″) to 0–76 mm (0–3″).”

The dual torch mount allows the use of two torches simultaneously. The machine can control two torches using the arc ignition cable plugged into the arc ignition socket.

GECKO Family: A Variant for Every Job

Whether operating in a fully equipped workshop or out in the field, there are several variants of GECKO carriage in PROMOTECH’s offer, each crafted to adapt seamlessly to different welding tasks and power supply standards.

Apart from the original GECKO version, described above in detail, in GECKO family of welding tractors consists of:

- a cordless GECKO Battery,

- a low voltage GECKO 42V,

- the high-speed GECKO HS and GECKO HS 42V.

Each model maintains the high-performance standards expected of PROMOTECH solutions, ensuring consistent weld quality and operational efficiency across diverse conditions.

GECKO HS (High Speed) – up to 220 cm/min

The GECKO HS is a carriage specifically designed for high-speed welding operations and plasma cutting, ideal for long welds or time-sensitive operations. With a horizontal travel speed of up to 220 cm/min, it significantly increases the efficiency of large-scale operations. Please note that GECKO HS works only in horizontal welding positions. Available in both 115–230V and 42V AC power supply options, as GECKO HS and GECKO HS 42V.

GECKO 42V AC – Low Voltage for Safety

Shipbuilding, offshore, and heavy industries – these industries often use carriages in harsh environments where moisture and other factors increase the risk of electrical hazards. A low-voltage variant helps minimize the risk of electrical shock, providing better protection for operators while maintaining outstanding performance. The GECKO 42V version offers a reliable and consistent power supply through its 42V AC connection that meets stricter safety protocols. Available also in high-speed HS-version for horizontal welding – GECKO HS 42V.

GECKO Battery / GECKO Battery 2

The new second-generation of a cordless variant of GECKO welding tractor, GECKO Battery 2 is enriched with practical improvements:

- Reinforced guide arms with the increased cross-section from 10 x 15 mm to 15 x 15 mm

- A built-in oscillator socket enabling direct powering of the OSC-8 PRO pendulum oscillator — eliminating the need for the external power supply

- Torch pre- and post-travel activation timing — ensuring optimal filling of the weld seam at both ends

Powered by a high-performance CAS LiHD battery, the GECKO BATTERY 2 delivers reliable, cable-free operation, significantly reducing the risk of accidents – a factor of key importance in demanding industrial environments, such as structural steel fabrication, shipyards, and pipeline construction sites.

Read more about PROMOTECH GECKO Battery 2 specification >>

All of PROMOTECH’s battery-powered machines — including welding and cutting tractors, portable bevellers, and drilling machines — operate with the same CAS-compatible batteries and chargers.

CAS (Cordless Alliance System) is a cross-manufacturer battery platform that unites over 40 leading power tool brands. It enables the use of one battery type across more than 300 different machines, offering unmatched flexibility, cost-efficiency, and convenience.

Discover cordless freedom powered by CAS >>

Whether you prioritize high-speed efficiency, mobility, safety in hazardous environments, or compatibility with various power supplies, PROMOTECH GECKO family of welding tractors delivers precision and reliability across all versions.