Welding Slang for Defects and Imperfections

Welding isn’t always sunshine and stack-of-dimes perfection. In real life, welds can go wrong – and when they do, welders often reach for a colourful set of slang terms. Welding slang is a creative way to diagnose mistakes, bond with the crew, and keep things honest on the job site. The humour keeps things light while staying honest. In this article, we explore the welding slang used to describe imperfections, defects, and just plain ugly welds.

Welds that go wrong

A mess of lumps, porosity, and poor fusion? That’s a Bubble Gum weld—sticky, ugly, and structurally questionable. Oversized, clumsy welds that lack finesse might earn the label Gorilla Weld, while random molten metal blobs hanging off the edge are known as Dingleberries.

Even though every defect is an imperfection but not every imperfection is a defect. So before we dive into the details of welding slang, let’s first clarify the difference between an imperfection and a defect.

Imperfections vs. Defects: What’s the Difference?

Welding Defect

A significant imperfection that compromises the weld’s structural integrity, strength, or safety. Such defects typically fail to meet quality standards and often result in rejection during inspections or testing.

Welding Imperfection

Any deviation from the ideal weld geometry or appearance. While it might look rough, irregular, or even earn a humorous nickname, such imperfections do not necessarily compromise the weld’s structural integrity or safety. These may not fail quality tests, but they sure offend a welder’s pride.

The welding slang for discontinuities

Among the discontinuities related to the welding process, one can mention 10 types.

| Welding Discontinuity | Common Causes |

|---|---|

| Lack of Penetration | Low current, improper joint design, fast travel speed, poor fit-up |

| Lack of Fusion | Insufficient heat, dirty surface, poor technique, fast travel speed |

| Undercut | High current, fast travel speed, wrong electrode angle, long arc |

| Spatter | High voltage/current, dirty workpiece, poor wire settings |

| Slag Inclusions | Inadequate cleaning, low heat input, poor manipulation, tight joints |

| Cracks | High residual stress, rapid cooling, poor joint design, incompatible filler |

| Porosity | Contaminated surfaces, improper shielding gas, long arc, wet electrodes |

| Overlap | Slow travel speed, excess filler, low heat input, poor angle |

| Warpage | High heat, lack of clamping, poor weld sequence, uneven cooling |

| Burn Through | Excessive heat/current, slow travel, thin base metal, poor technique |

Let’s breakdown of welding slang for them:

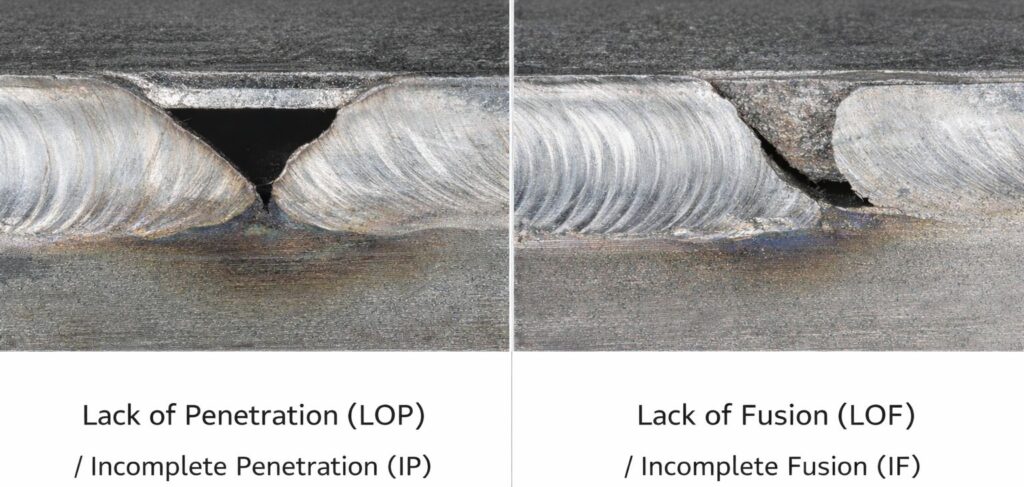

1. Lack of Penetration (LOP) / Incomplete Penetration (IP) – welds that didn’t go deep enough

- Cold joint – no proper bond to the base metal, often due to low heat

- Lazy bead – just sits on the surface with no depth

- No root – no weld at the root of the joint

- ROMF (Run Out of Material Fix… meaning it is really bad)

2. Lack of Fusion (LOF) / Incomplete Fusion (IF) – sits on top without proper bonding to the base or previous weld pass

- Cold lap – overlaps without bonding; looks like it’s “lying on” the base metal

- Unstuck weld – the bead that isn’t fused

- Cold roll, Rolled bead – bead formed but not fused; rolls off easily

- Slide ‘n ride – over without bonding

3. Undercut – a groove melted into the base metal next to the weld toe.

Common causes include excessive welding current, high travel speed, or improper electrode angle.

- Valley weld – the groove beside the weld looking like a valley

- Gutter – a deep groove along the edge

- Edge groove – melted base metal that wasn’t filled back in

- Meltback – base metal melted away, leaving a notch

4. Spatter– small molten metal droplets scattered across the surface, a common byproduct of MIG welding gone wild

- Bs, BBs or Buckshot

- Popcorn when the texture is rough

- Chicken feed scattered like birdseed

- Gremlins – random bits of weld metal showing up where they shouldn’t

5. Slag Inclusions – non-metallic material trapped inside the weld

- Worms resemble little trails or worm-like shapes embedded in the metal

- Cinders like burnt embers. leftover slag that didn’t get cleaned out

- Baked-in trash – foreign material sealed into the weld

- Trapped junk – anything stuck inside the weld

6. Cracks – fractures in or next to the weld, can be hot or cold cracks

- Snake bites – Small, sharp cracks that resemble fangs or slits.

- Break lines – Straight fractures in the weld.

- Zippers – a crack runs along the weld seam, resembling the unzipping of a zipper

- Split seam – a weld seam that has opened due to stress or shrinkage

7. Porosity – gas bubbles trapped in the weld bea

- Bugholes or Pinholes – tiny surface holes

- Swiss cheese – weld full of holes

- Bubble weld – looks like bubbles froze in the metal

Wormholes, worm trails, worm channels – long pores or gas paths inside or just below the weld

8. Overlap weld metal flows beyond the weld toe without fusing

- Soggy bead – Droopy weld bead that didn’t fuse

- Melted pancake – Flat and spread-out bead sitting on the surface

- Lazy roll – Bead that just “rolled” over the edge without fusion

- Slouch weld – Bead slouched over, poor technique

9. Warpage caused by uneven heating and cooling

- Banana metal – workpiece bent like a banana

- Potato chip – thin parts warped into a wavy or curled shape

- Twist and shout – twisted metal

- Heat wave from thermal stress

10. Burn Through hole created when too much heat melts through the base metal

- Blowout – A hole blown through the metal

- Oops hole – Obvious mistake—too much heat, hole formed

- Melt-through – Metal completely melted away; often visible on back side

How Does Welding Automation Help Eliminate Imperfections?

Welding slang might be funny, but it also carries a lesson, helping workers identify problems, poke a little fun, and — ideally — learn how to avoid making the same mistake twice. And to make life easier, maybe just use welding automation?

Precision and Consistency Through Automation

Beyond improving weld integrity, automation also enhances productivity and process reliability, ensuring every weld meets the same high standard. Employing welding tractors or heavy-duty welding automation systems minimizes the risk of human error and ensures complete control over key parameters such as travel speed, torch angle, and arc length.

Consistent movement and stable torch positioning eliminate common welding defects — including undercuts, porosity, and irregular bead geometry — while allowing even less experienced operators to achieve professional-quality results with minimal training. The result is a uniform, high-quality weld with repeatable precision — even during long or demanding production runs.