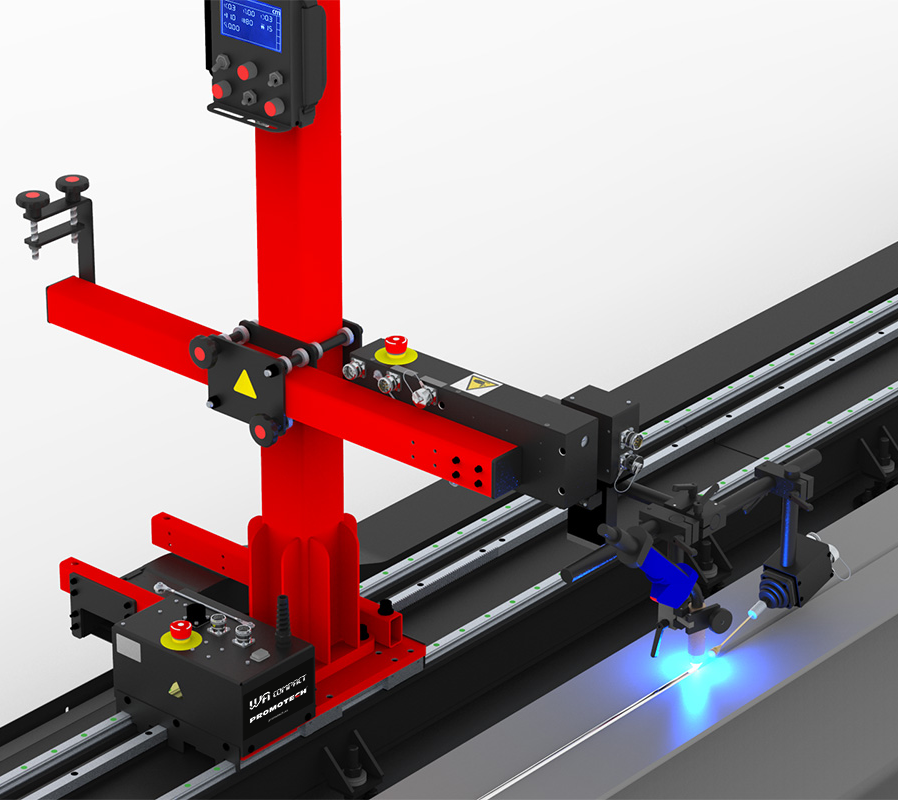

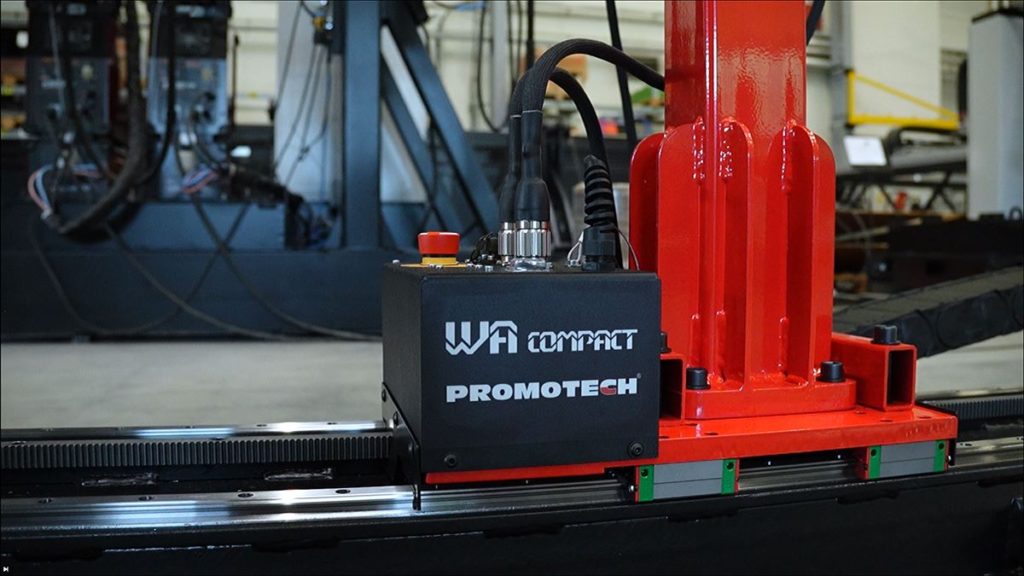

WA Compact – cost-effective and space-efficient solution

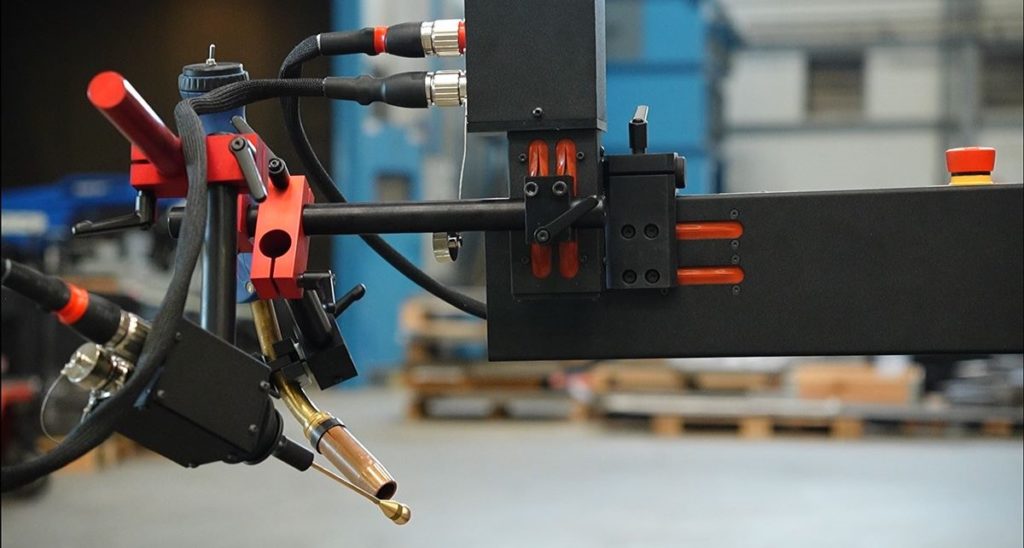

The WA Compact Welding System is an advanced and versatile solution engineered for making both continuous and stitch butt and fillet welds, using the MIG/MAG method. Equipped with a joint tracking system for active vertical and horizontal torch compensation, the WA Compact delivers enhanced precision without taking the space or cost of the gantry system.

Users will surely appreciate the cost-effective and space-efficient nature of WA Compact. Positioned between a welding tractor and a WA gantry system, it combines the mobility of a trolley with the structural stability of a column-guided setup.

This makes the WA Compact a practical choice for both workshops and large-scale industrial operations— especially where space optimization is a priority.

WA Compact enables a wide range of welding joint applications.

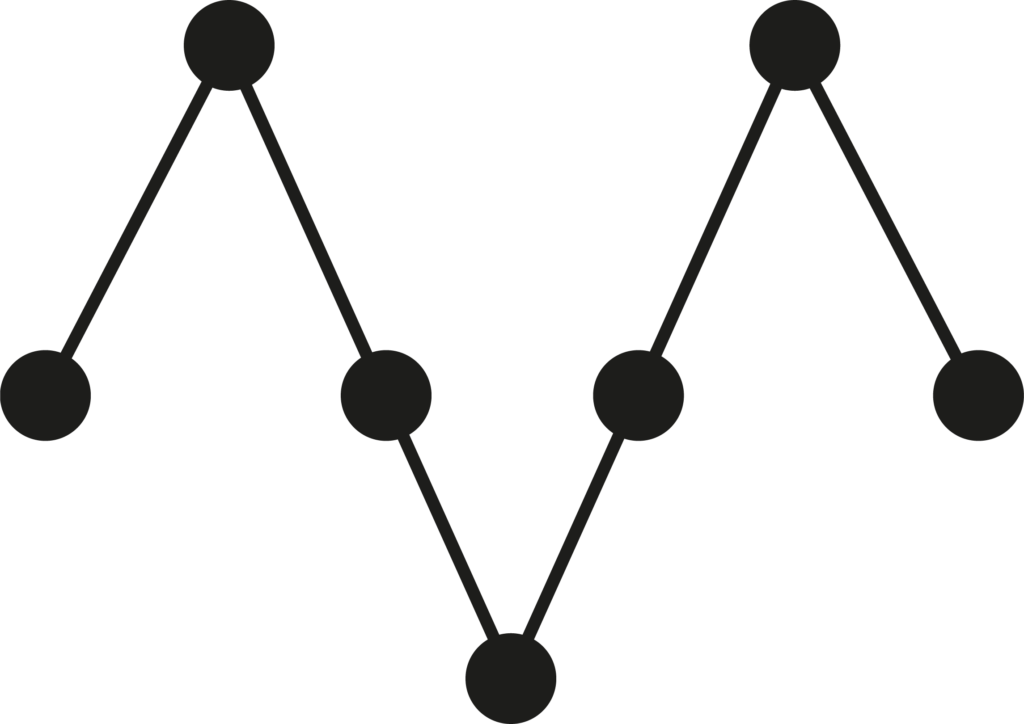

This welding system can operate with or without oscillation, offering flexibility for a wide range of welding applications. It supports multiple oscillation patterns— straight, triangle, trapezoid, and square—which enhances its adaptability to different joint types and welding technology.

| Path | Description |

|---|---|

|

Triangle: The machine travels only during oscillation. During oscillation dwell time, the machine stops to fill the crater. |

| Trapezoid: The machine travels at all times, also during oscillation dwell time. | |

|

|

Square: The machine travels only during oscillation dwell time in left and right position. During oscillation, the machine stops. During oscillation dwell time in center position the machine fills the crater. |

The oscillator and motorized vertical slide keep the torch correctly aligned with the seam throughout the welding process. This ensures consistent penetration, proper fusion, and a smooth weld bead, while effectively preventing common defects such as undercut, porosity, and lack of fusion.

Ergonomic remote control pendant

The handheld operator terminal features a clear, intuitive layout and easy-to-operate control knobs, allowing for quick adjustments — even without lifting the operator’s welding helmet. Its user-friendly interface enables precise and convenient setting and fine-tuning of a wide range of welding parameters, including:

- Travel speed

- Torch height

- Total welding length – once this length is reached, the machine behaves as if a limit switch has been triggered

- Space before welding

- Crater fill time before and after welding

- Oscillation offset

- Oscillation width: 0 to 114 mm (0–4 31/64″)

- Oscillation speed: 0.1 to 2 m/min (4–79 inch/min)

- Oscillation dwell time at the centre, left, or right position (0–5 seconds)

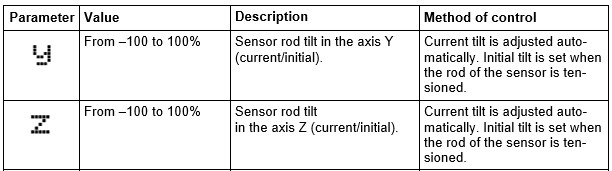

- Sensor rod tilt: in the Y-axis (current/initial) and Z-axis (current/initial)

When the stitch welding option is activated, the pendant enables additional settings for stitch-specific parameters:

- Weld length

- Space between welds

- Backweld length

- Crater fill time at the weld end

- Behaviour of the arc ignition relay while filling the crater

In addition, the operator can quickly switch between metric and imperial units (centimetres or inches) for added convenience.

Sensor rod tilt adjustment

The WA Compact Welding System features sensor rod tilt on both the Y and Z axes, this means that the angle of the sensor rod can be adjusted both horizontally (Y-axis) and vertically (Z-axis). This dual-axis adjustment ensures optimal tracking accuracy and reliability across diverse welding scenarios.

“Initial %” and “Current %” in Tilt Monitoring

Initial % shows the baseline sensor rod tilt tension in either the axis Y or the axis Y. It is set when the rod of the sensor is first tensioned. This Initial % typically ranges from 7% to 10%. In contrast, the Current % reflects the real-time tilt tension, which is continuously monitored and automatically updated to capture any changes during operation.

Perfect Torch Alignment

WA Compact’s advanced joint tracking system is designed to maintain optimal torch positioning. Moreover, operators can select between tracking in the Y axis, the Z axis, or both Y and Z axes simultaneously, depending on the application and their specific needs.

Y Axis Tracking (Lateral Tracking)

Tracking in the Y axis—the side-to-side direction—keeps the torch precisely centred over the weld seam without making unnecessary vertical adjustments. This mode is used when:

- the weld seam may shift horizontally due to material placement or distortion,

- the workpiece surface is flat and consistent in height,

- accurate centering of the torch over the seam is the primary goal.

Benefit: Optimal alignment along the seam with stable, controlled motion.

Z Axis Tracking (Vertical Tracking)

Tracking in the Z axis — the up-and-down direction — ensures consistent arc length and weld penetration, even when the surface height varies. This option is ideal when:

- the material surface is uneven, curved, or wavy (e.g., pipes, rolled plates),

- there are variations in material thickness,

- the weld seam is straight, but maintaining a consistent arc height is essential.

Benefit: Maintains steady arc parameters and high-quality welds in fluctuating vertical conditions.

Dual-Axis Tracking (Y + Z)

The Y + Z tracking mode is the most advanced option, enabling the system to dynamically adjust both the lateral and vertical position of the torch in real-time. Recommended for:

- complex weld geometries (curved or irregular seams),

- high-precision applications,

- automated production environments where repeatability and consistency are critical.

Benefit: Delivers maximum control, ensuring top-tier welding quality regardless of seam variability.

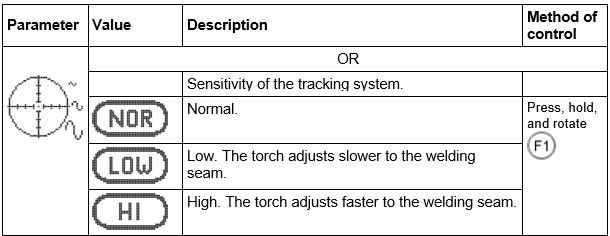

Sensitivity of the tracking system

Tracking sensitivity determines how responsive the welding torch is to changes or deviations in the weld joint path which may arise from groove preparation variations, part misalignments, thermal deformation, or material movement. In the WA Compact Welding System, the user can individually set the sensitivity level of the tracking system to one of three options: low, normal, or high.

In welding automation, “better” doesn’t mean more sensitive – it means more appropriate for the job. The setting must be matched to the specific application, not the other way around.

Low Sensitivity

Low sensitivity provides a stable torch path and reduces unnecessary corrections. It is best suited for uniform welds on thick, rigid components, where the weld seam is well-prepared and predictable. This setting is ideal when the operator wants to avoid reactions to minor, irrelevant surface variations.

Normal Sensitivity

Normal sensitivity offers a balanced compromise between responsiveness and stability. It is recommended for most standard, typical welding applications, where minor seam deviations may occur but do not require aggressive compensation. This is often the default and most universal setting.

High Sensitivity

High sensitivity, on the other hand, enables the torch to respond quickly to even slight deviations in the weld seam path. It is especially useful for welding applications involving thin sheets or flexible materials, deformed components, or irregular joint paths.

To sum up, choosing the highest sensitivity level is not always the most optimal choice. The right sensitivity level should be based on real weld conditions and component characteristics, ensuring the welding system delivers both accuracy and reliability in line with the specific task requirements.

Limit Switch: Automatic Stop at End of Weld

The primary purpose of a limit switch is to automatically stop the machine at the end of a weld seam. This is especially useful in situations where the operator cannot precisely stop the machine manually without risking overweld or run-off, long, straight welds, or the repetitive tasks.

When the limit switch is activated (for example, when the set welding length is reached), the WA Compact system automatically stops. What happens next depends on the selected setting— operator can choose from three practical options:

Option 1: Quick 10 mm Reverse

Stops the machine and arc. To continue, set the direction switch to ‘O’ (neutral). The machine will automatically move back 10 mm (25/64″) and clear the stop signal. Ideal for minor corrections or preparing for the next weld quickly.

Option 2: Return to Start Position

The arc stops and the machine automatically travels back to the original starting point of the weld. Once it gets there, set the direction switch to ‘O’ to remove the stop signal. Useful when you want to repeat the weld or reposition for another run.

Option 3: Manual Choice Between 1 and 2

This is the most flexible option, giving the operator full control over what happens next.

Both the machine and arc stop. You can now decide how to continue: Press F1, F2, or F3 to return the machine to the start position (like in Option 2). Or set the direction switch to ‘O’ to move back just 10 mm (like in Option 1).

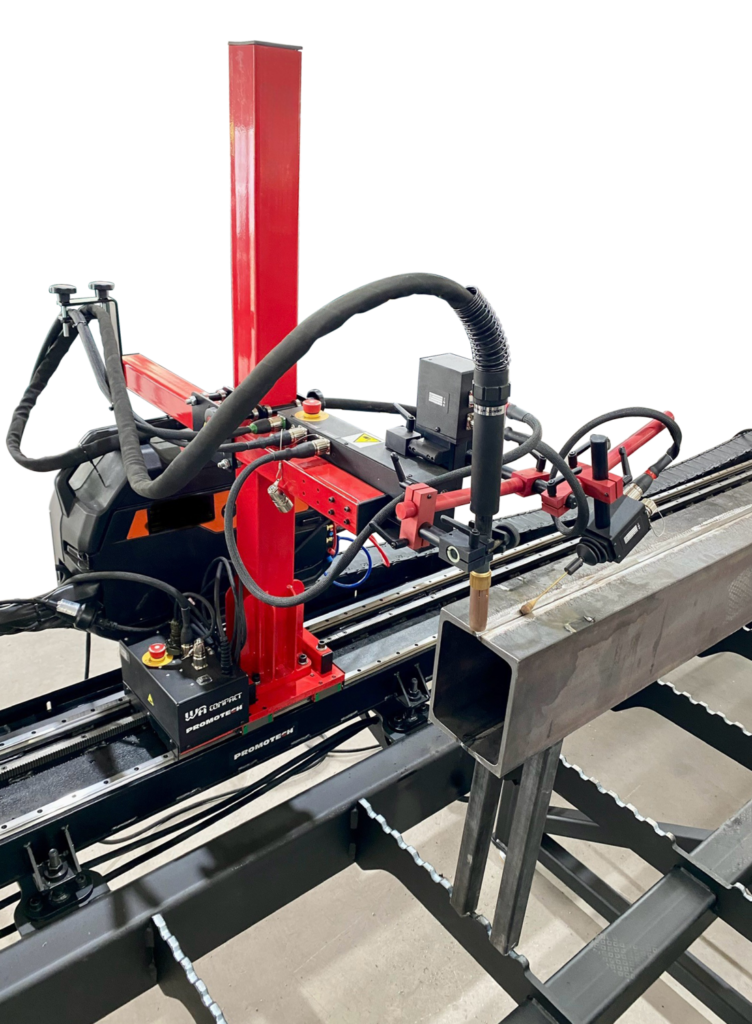

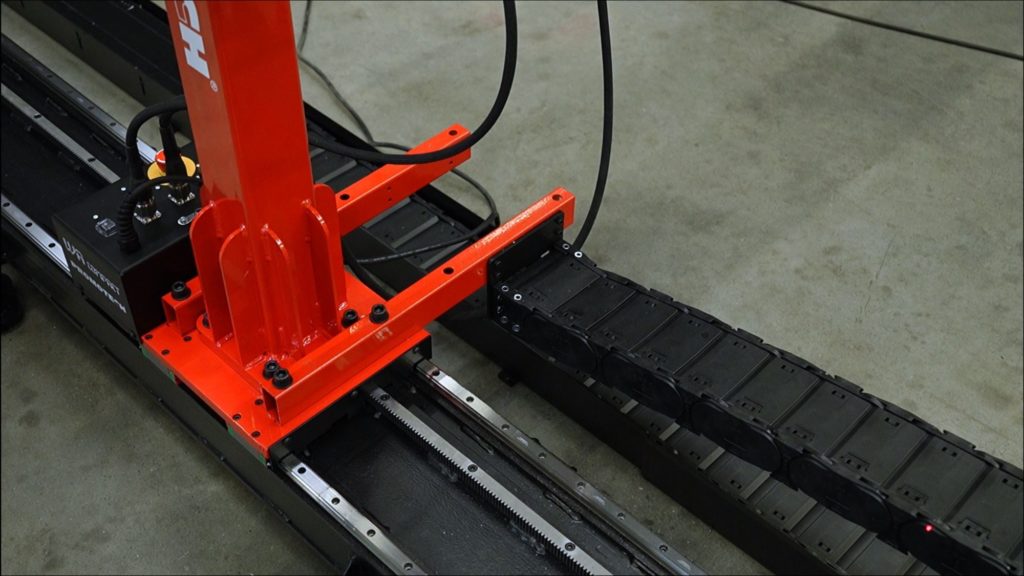

Modular Track System for WA Compact

The WA Compact welding system travels along a modular track, delivering precise and stable movement throughout the entire welding process. While the standard minimum track length is 4 meters, the system is built from 2-meter support modules, allowing for highly flexible configurations. To meet specific project needs, the track can be extended using additional 2-meter long inner segments, up to a total length of 20 meters.

The WA Compact is a cost-effective yet technologically advanced welding solution designed to boost productivity and minimize process time. Whether in shipbuilding, construction, or general fabrication, WA Compact delivers high-quality welds without compromising on performance — making it the perfect choice for industries where budget and space are limited, but weld quality is non-negotiable.

WA Compact – Technical specification

- Power 200 W

- Torch type MIG/MAG

- MIG/MAG torch diameter 16–22 mm (5/8″–55/64″)

- Horizontal speed 0,05–2,5 m/min (2–98 inch/min)

- Standard torch travel length * 3.5 m

- Standard overall track length * 4 m

- Oscillation type Linear

- Weld path Straight, triangle, trapezoid, square

- Oscillation width 0–114 mm (0–4 31/64″)

- Oscillation speed 0,1–2 m/min (4–79 inch/min)

- Oscillation dwell time at centre and on ends 0–5 s

- Maximum oscillator pulling force 50 N

- Weight 484 kg