GECKO Battery 2 – the New Generation of Cordless Welding Versatility

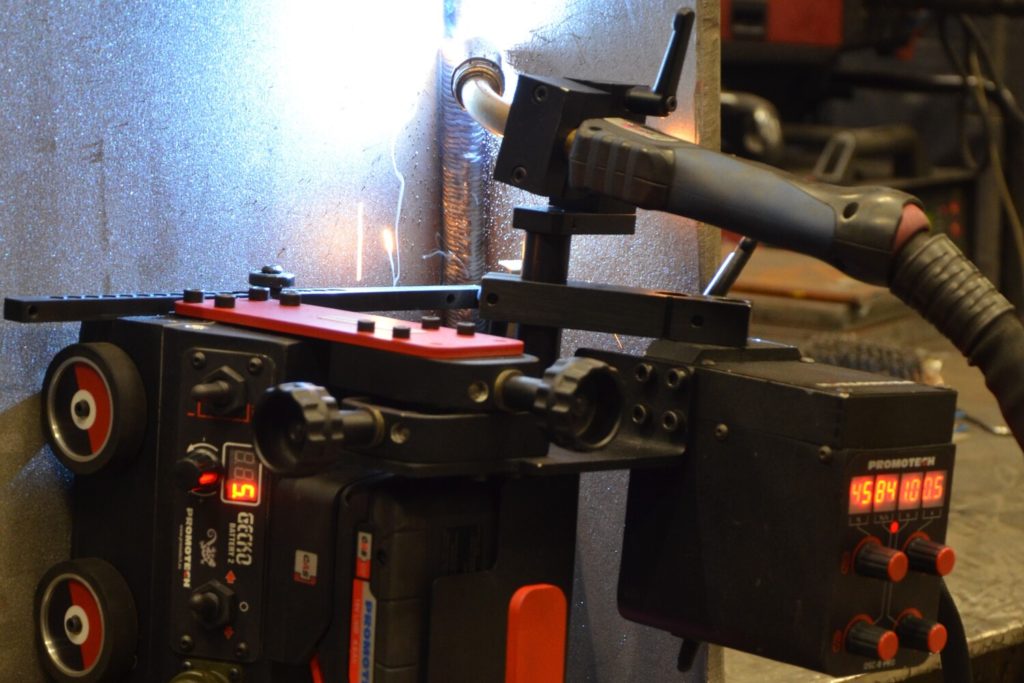

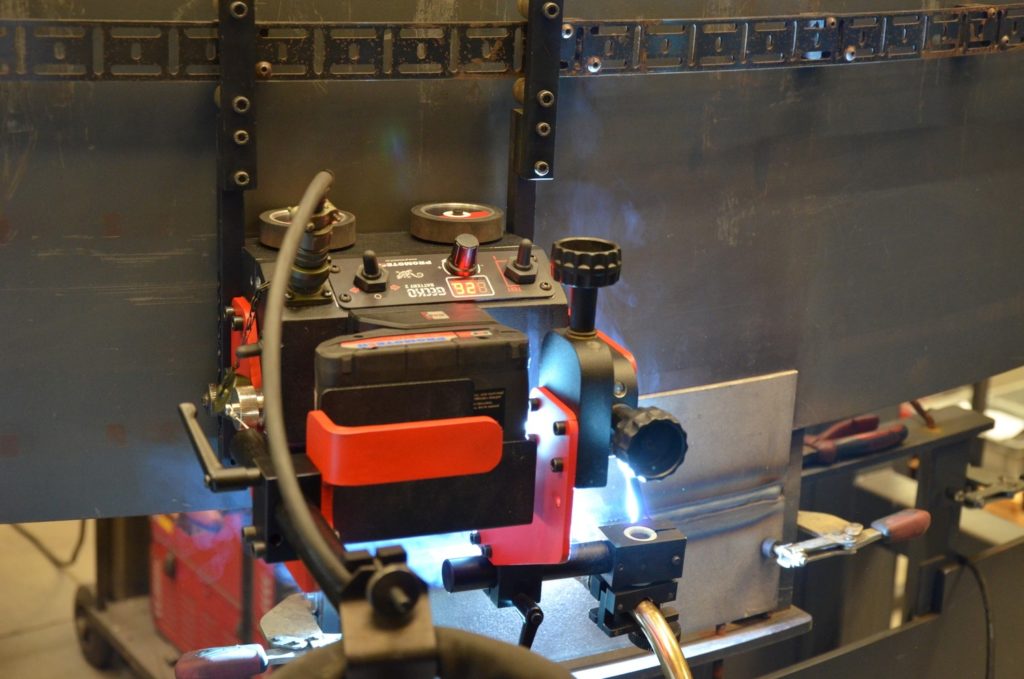

GECKO Battery 2 carriage produces continuous butt and fillet welds on carbon steel, stainless steel, and aluminium, using MIG/MAG torches. Its compatibility with a wide range of optional accessories makes the GECKO family of welding tractors exceptionally versatile — a key reason behind its lasting popularity among professionals across various industries.

Safety First

Powered by a high-performance CAS LiHD battery, the GECKO BATTERY 2 delivers reliable, cable-free operation, significantly reducing the risk of accidents – a factor of key importance in demanding industrial environments, such as structural steel fabrication, shipyards, and pipeline construction sites.

Without a power cable connected to the mains, there is no contact with high voltage, which minimizes the risk of electric shock. This is particularly important in conditions where moisture, conductive metal surfaces, and limited space are common. Traditional power cables are easily damaged by heavy equipment, sharp edges, or welding spatter, and once compromised, they can cause short circuits, sparking, or even fires.

GECKO Battery 2 – new generation

In response to valuable feedback from users of the GECKO family of welding tractors, the new-generation GECKO BATTERY 2 introduces three practical enhancements:

- A built-in oscillator socket enabling direct powering of the OSC-8 PRO pendulum oscillator — eliminating the need for the external power supply

- Torch pre- and post-travel activation timing — ensuring optimal filling of the weld seam at both ends

- Reinforced guide arms with the increased cross-section from 10 x 15 mm to 15 x 15 mm

Now, with these new features, the GECKO Battery 2 delivers safety, precision and flexibility — without the hassle of additional cables, even when an oscillator is required. By operating cable-free, the GECKO BATTERY 2 ensures a cleaner, more organized workspace and reduces the risks of accidents and electric shock.

Direct Power Supply for Oscillator – No Extra Cables Needed

With a built-in socket, the OSC-8 PRO oscillator can be plugged directly into the GECKO BATTERY 2 welding tractor, eliminating the need for external power sources or additional wiring. This plug-and-play simplicity saves valuable setup time, increases safety, comfort of use and overall ergonomics.

A battery-powered welding tractor with a built-in oscillator socket isn’t just convenient — it’s a performance booster. And at just over 8 kg, this compact, portable tractor can be carried anywhere.

Configuration with optional pendulum oscillator OSC-8 PRO

New OSC-8 PRO oscillator with digital LED display enables precise setting and reading of weave width, weave speed, and left/right side dwell times. It also shows the current status of the OSC-8 PRO and provides safety and diagnostic information.

Using PROMOTECH’s OSC-8 PRO weave welding solution significantly reduces spatter and material waste, eliminating the need for rework and minimizing post-weld clean up.

The OSC-8 PRO ensures optimal material deposition and better fusion between the base metal and weld metal — particularly in thicker sections. During welding of wide grooves or gaps, oscillation enables the formation of wider weld beads in a consistent weaving pattern, effectively covering larger areas. It adapts to various joint geometries by producing triangular or trapezoidal oscillation paths, while multi-layer welding ensures strong, high-integrity joints.

Read more about OSC-8 PRO pendulum oscillator with LED display >>

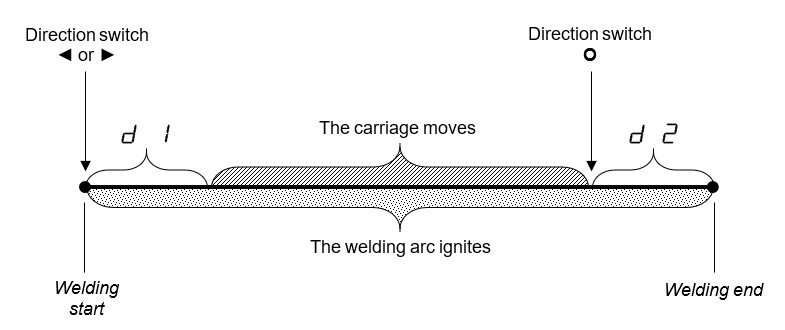

Pre-Setting Torch Activation Time

The upgraded GECKO BATTERY 2 now offers the ability to pre-set arc ignition timing — up to 5 seconds – at the start and end of travel. Previously available only in other variants of GECKO family tractors (GECKO, GECKO HS, GECKO HS 42V, and GECKO 42V), this practical function is now also available to users who require cordless mobility.

| Parameter | Value | Description |

|---|---|---|

| d 1 | 0–5 s [step: 0.5 s] |

Carriage movement delay time. When the direction switch is set to ◄ or ►: d 1 = 0 s – the arc ignites and the carriage starts immediately, d 1 > 0 s – the arc ignites and the carriage starts after the set time. |

| d 2 | 0–5 s [step: 0.5 s] |

Arc out delay time. When the direction switch is set to O: d 2 = 0 s – the carriage stops and the arc goes out immediately, d 2 > 0 s – the carriage stops and the arc ignites for the set time. |

Why Pre-Setting Arc Ignition Time Is Helpful?

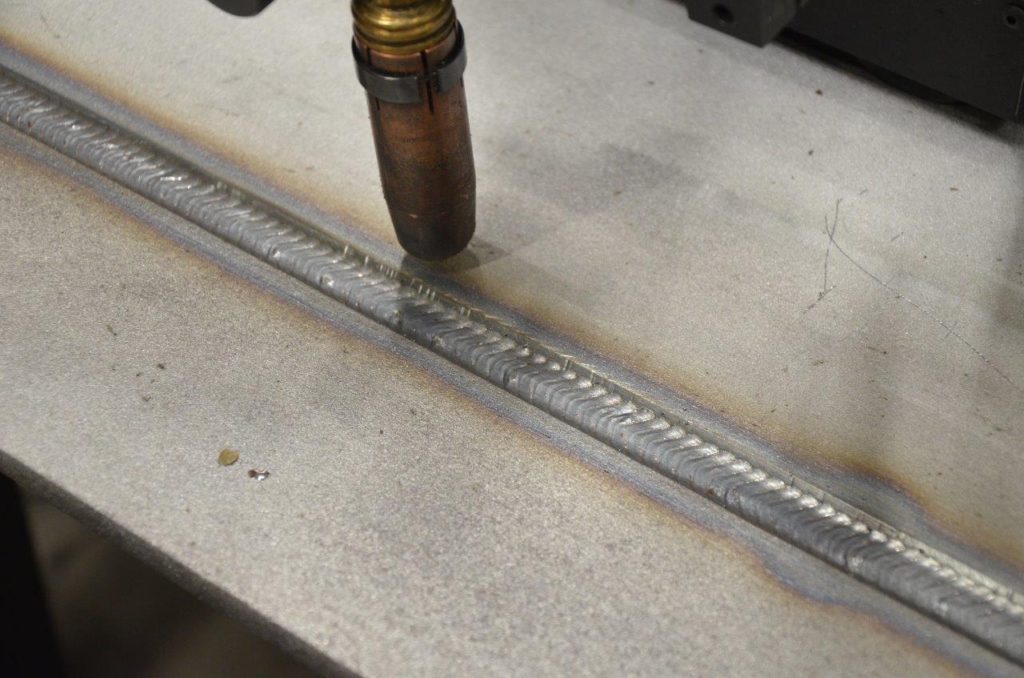

Welds are only as strong as their weakest points, and those weak points are often found at the very start and end of the weld path. Cold starts can lead to underfilled joints and the lack of fusion, while end craters are prone to cracking — both of those issues can compromise the entire weld.

The GECKO BATTERY 2 addresses these issues directly by allowing the welding arc to ignite slightly before the carriage begins to move and remain active briefly after it stops. This simple pre-set time delay creates controlled weld build-up — known as crater fill — precisely where it’s needed most: at the start and stop points.

The result is not just improved integrity and mechanical strength but also a smoother, more consistent weld bead across the entire length of the joint. This leads to better visual appearance and minimizes variability between parts — important in production lines or critical fabrications. It also reduces the need for post-weld rework or grinding, reducing both labour time and material waste.

The advantage becomes even more apparent when working with challenging materials like stainless steel, aluminium, or other materials prone to thermal stress and end crater cracking, particularly in automated or semi-automated setups. A short delay in arc timing eliminates these problems by ensuring a gradual thermal transition and more complete fusion at both ends of the weld.

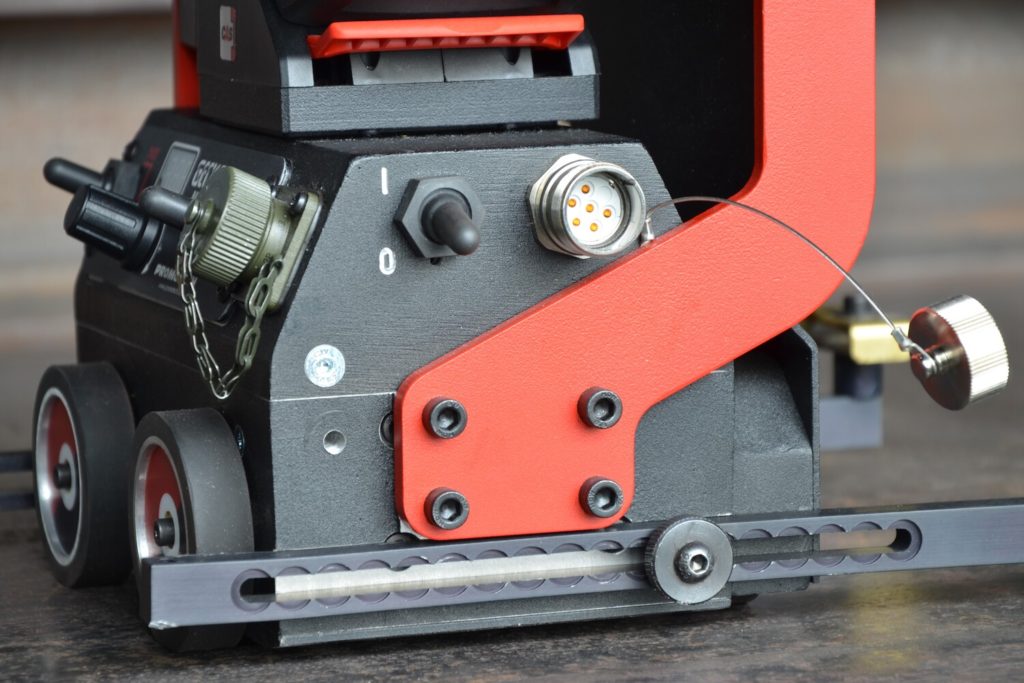

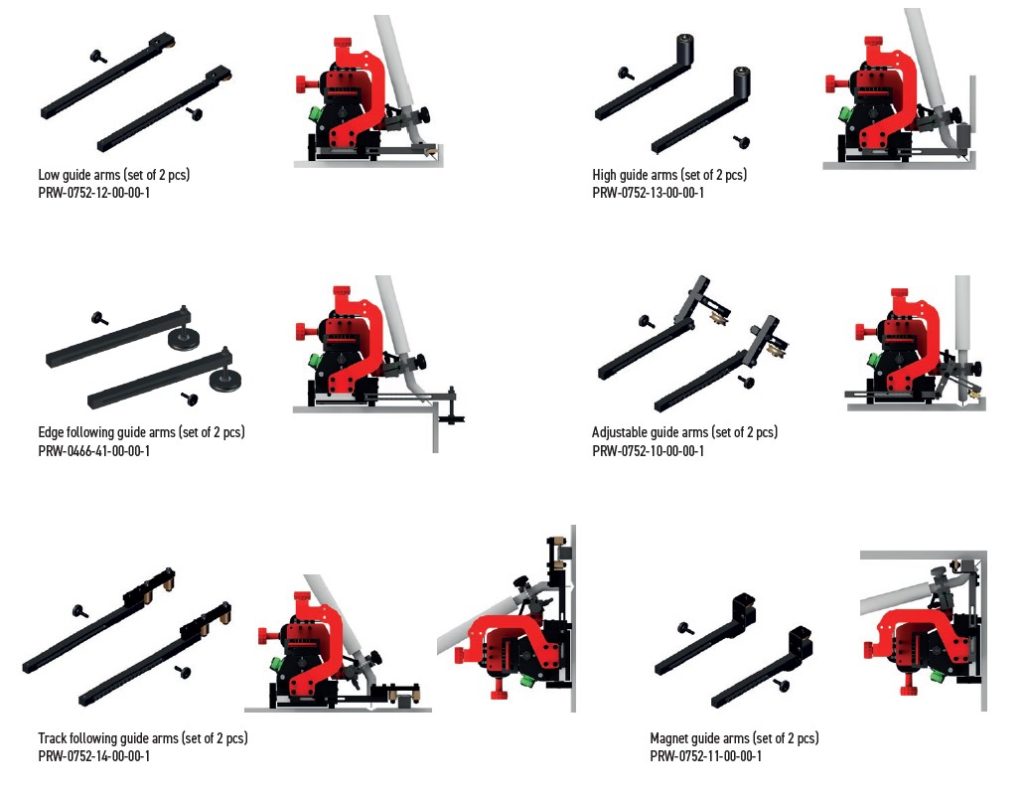

Reinforced guide arms

New guide arms now feature increased cross-section from 10 x 15 mm to 15 x 15 mm – for better durability and resistance. Each set of the new guide arms comes with two long screws with knurled nuts for easy and secure installation.

- Standard guide arms (set of 2 pcs) – new product code: ZST-0752-17-00-00-1

- Adjustable guide arms (set of 2 pcs) – new product code: ZST-0752-10-00-00-1

- Magnet guide arms (set of 2 pcs) – new product code: ZST-0752-11-00-00-1

- Low guide arms (set of 2 pcs) – new product code: ZST-0752-12-00-00-1

- High guide arms (set of 2 pcs) – new product code: ZST-0752-13-00-00-1

- Follower guide arms for flexible track (set of 2 pcs) – new product code: ZST-0752-14-00-00-1

- Edge following guide arms (set of 2 pcs) – product code: PRW-0466-41-00-00-1

Remarkable cordless versatility

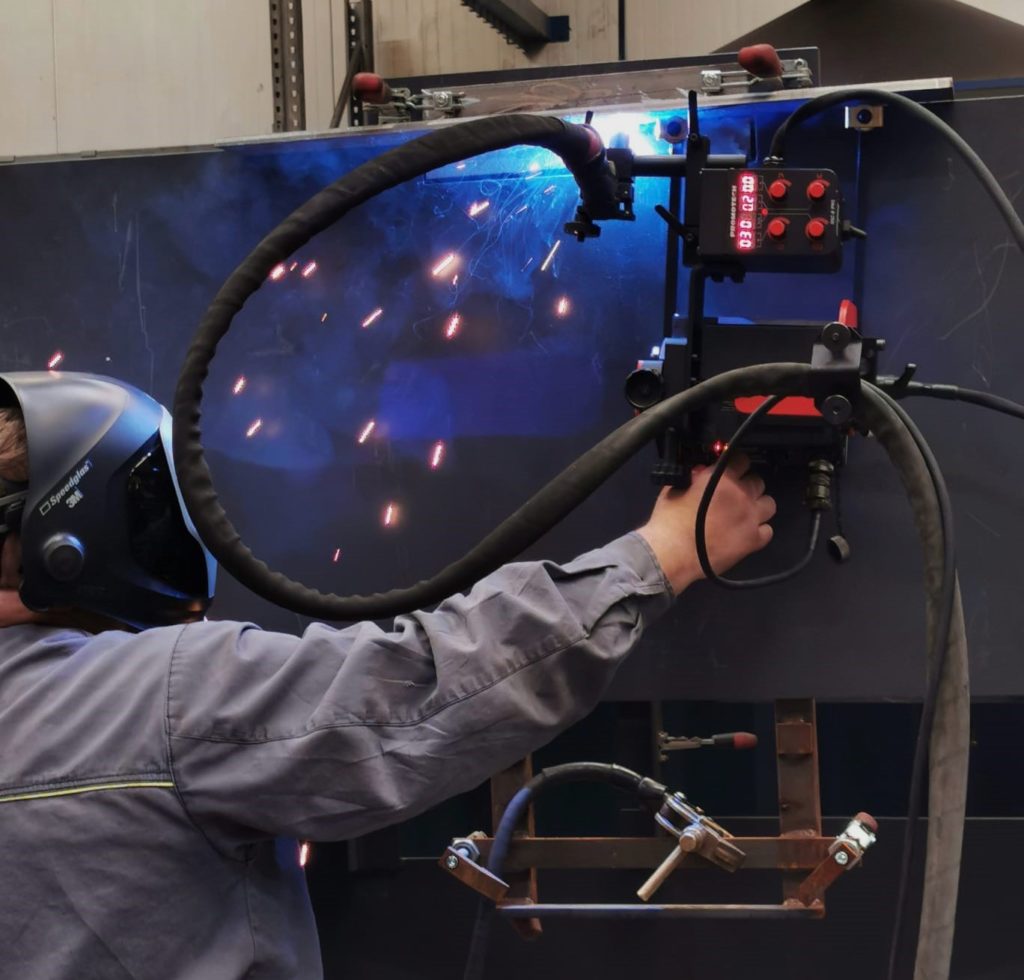

Thanks to its wide range of optional accessories, the GECKO Battery 2 welding carriage easily adapts to complex welding geometries. Digital speed control system with a built-in feedback loop ensure stable travel speed, even across vertical, overhead, and angled positions. GECKO Battery 2 can travel along outside edges, lap joints, and templates, and maintains reliable operation on low or perforated surfaces, ceilings, pipes, and tanks.

Wide Range of Welding Positions

With optional accessories, GECKO Battery 2 welding tractor can be easily adapted to support a wide range of welding applications, including complex out-of-position tasks.

The GECKO BATTERY 2 is engineered for welding in various positions:

- PA / 1F / 1G – Flat Position

- PB / 2F – Horizontal Fillet Position

- PC / 2G – Horizontal Groove Position

- PD / 4F – Overhead Fillet Position

- PE / 4G – Overhead Groove Position

- PF / 3G – Vertical Up Groove Position

With enhanced capabilities — a built-in oscillator socket, compatibility with the advanced OSC-8 PRO pendulum oscillator, and the ability to pre-set the pre- and post-travel torch activation — the GECKO Battery 2 offers safety, exceptional portability and true cordless freedom: no power cables, no limitations.

Powered by a high-performance CAS battery system, it’s part of a cross-brand platform that supports over 300 tools from more than 40 manufacturers, including all PROMOTECH cordless solutions — from welding and cutting tractors to portable bevellers and magnetic drilling machines.

Read more about cordless mobility offered by CAS battery system >>

Battery-powered machines are not only about convenience and flexibility but, above all, an important step toward increased safety. Whether welding carbon steel, stainless steel, or aluminium — in flat, vertical, or overhead positions — the GECKO Battery 2 provides a compact, reliable, and user-friendly solution that reduces rework, boosts productivity, and excels in the most demanding industrial environments.

If you would like to learn about the GECKO family of welding tractors, check also: