PRO-152T | Tapping and Drilling Machine

The PRO-152T mag drill enables a milling capacity of up to 150 mm and a drilling capacity of up to 47 mm. Forward & reverse work modes allow tapping of through holes up to M42 and blind holes up to M33 with Promotech’s tapping system. A four-speed gearbox with continuous speed adjustment allows one to set optimal speed depending on diameter, steel grade, or tool quality. An intelligent speed control system maintains constant motor speed regardless of changing loads, whereas both overload and overheat protection prevent misuse of the machine.

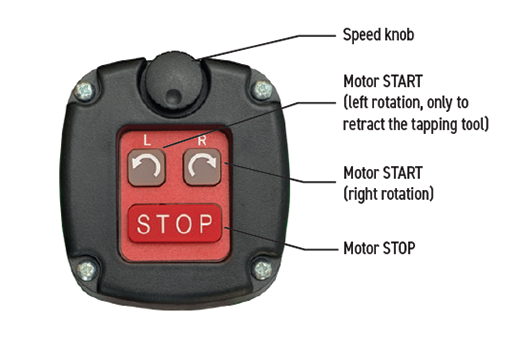

- Integral forward/reverse operation – the ability to tap pre-drilled holes up to M42

- 360-degree visual monitoring system indicates the current condition of the drill and gives safety and diagnostic information, e.g. worn brushes

- Electronic Speed Stabilization System (ESSS) maintains stable speed regardless of load changes

- Rigid casting designed to withstand downward drilling force, prolonging the tool’s life

- Tilt sensor – to stop the motor if the machine breaks away from the surface whilst in operation

- Semi-automatic gib adjustment enables simple, fast, correct, and repeatable slide backlash settings without any expert knowledge or experience

- Energy Saving Base (ESB) uses only 50% of its power when the motor is not running

- Magnetic Field Shape Control (MFSC) provides maximum holding power on thin materials