SBM-500 | Stationary Bevelling Machine

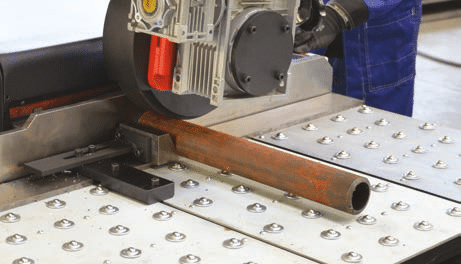

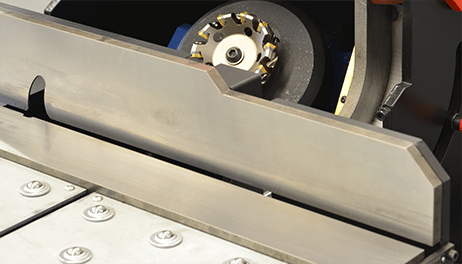

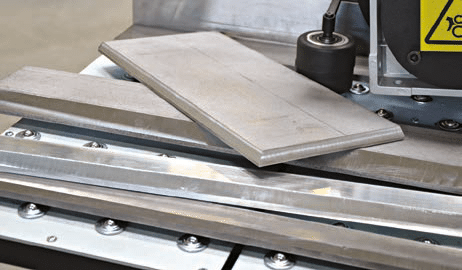

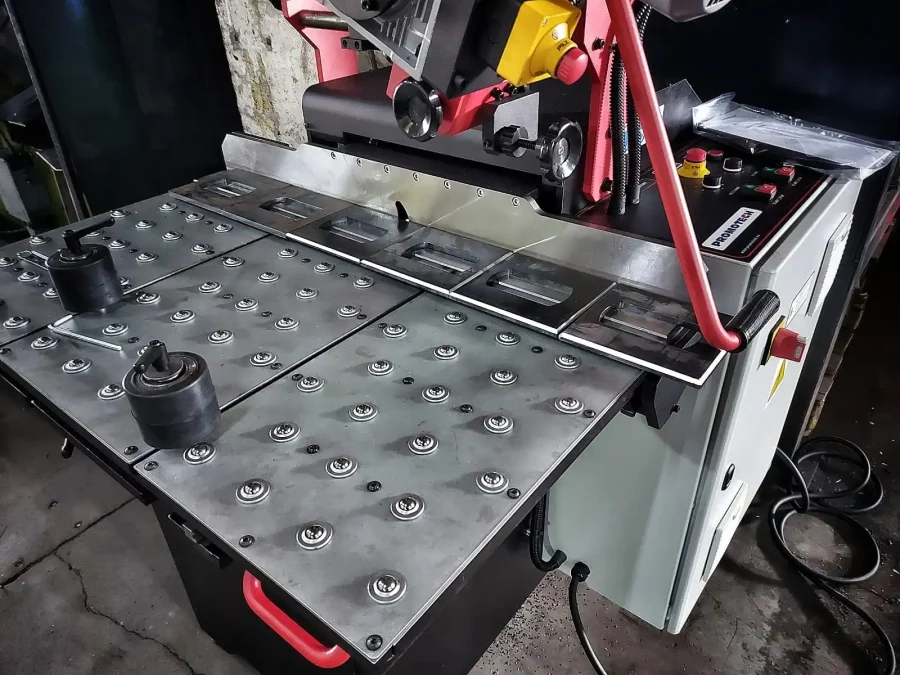

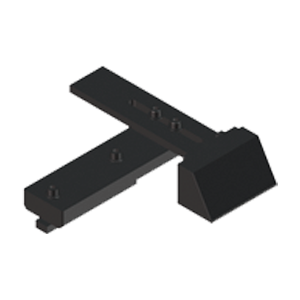

Equipped with a powerful 7.500-watt motor, the stationary beveling machine is a robust and efficient solution for beveling up to 30 mm wide on different-sized workpieces up to 100 mm thick and small pipes from 50 to 150 mm in diameter. The SBM500 features a high-speed rotary milling head that produces a clean, milled surface without thermal distortion or a heat-affected zone. Continuous adjustment of spindle speed and auto-feed rate makes it suitable for different types of steel and aluminum. Optional accessories expand the possible applications of the SBM-500 to deal with long workpieces, pipes 50-150 mm OD, and narrow workpieces with a minimum width of 30 mm.

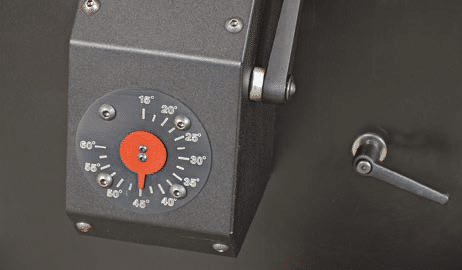

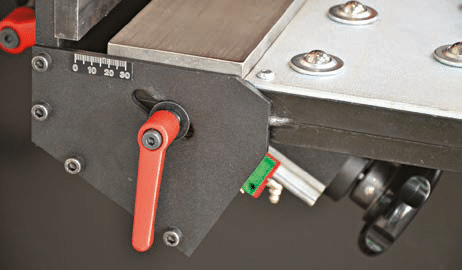

- Precise setting of bevel angle from 15 up to 60 degrees and bevel width up to 30 mm

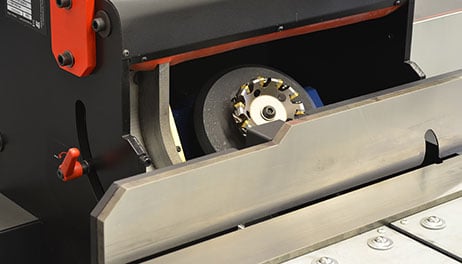

- 3D contact wheel control ensures proper workpiece alignment in relation to high-speed rotary milling head

- variable auto-feed to bevel both ferrous and non-ferrous materials

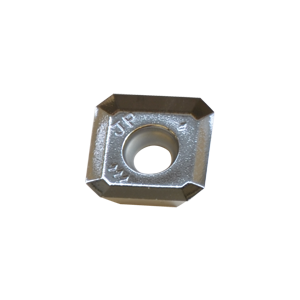

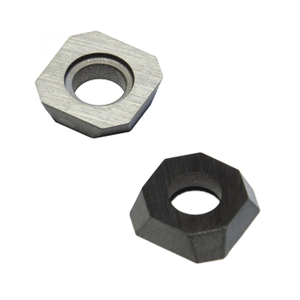

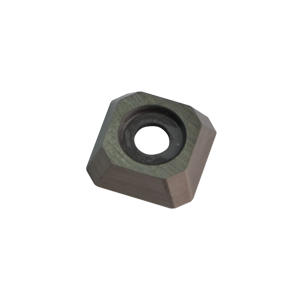

- cutting inserts dedicated for optimal performance on different materials

- easy access to milling head and cutting inserts

- overload protection to prevent motor damage

- SBM-500 streamlines workflow to maximize your production efficiency