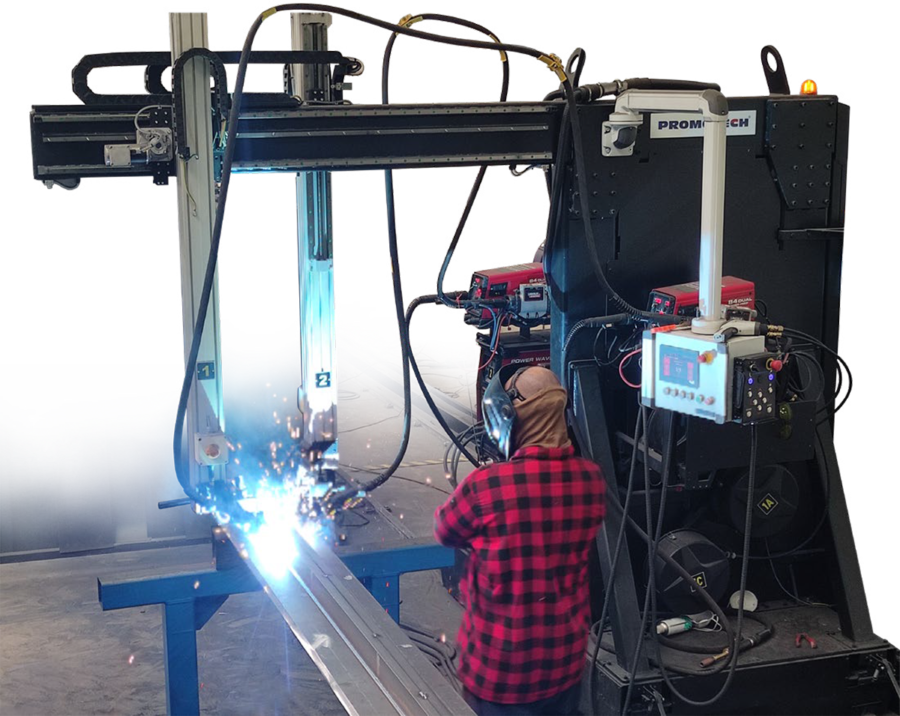

WA 1500 HD / WA 2000 HD

Automatic longitudinal top quality MIG-MAG or SAW welding of long structural Box beams and H, I, T, HKS, HSQ also automotive chassis for long truck/train beams. Single or multipass automatic fillet/butt welding with an electromechanical joint tracking system. Minimized welding defects and reduced non-productive time and it’s one-man operation!

- Automatic fillet and butt welding with joint tracking

- Multipass welding

- One-man operation

- Reduction of costly over-welding and decrease in filler metal usage

- User-friendly interface – multiple languages

- Accepts most of MIG-MAG and SAW welding power sources