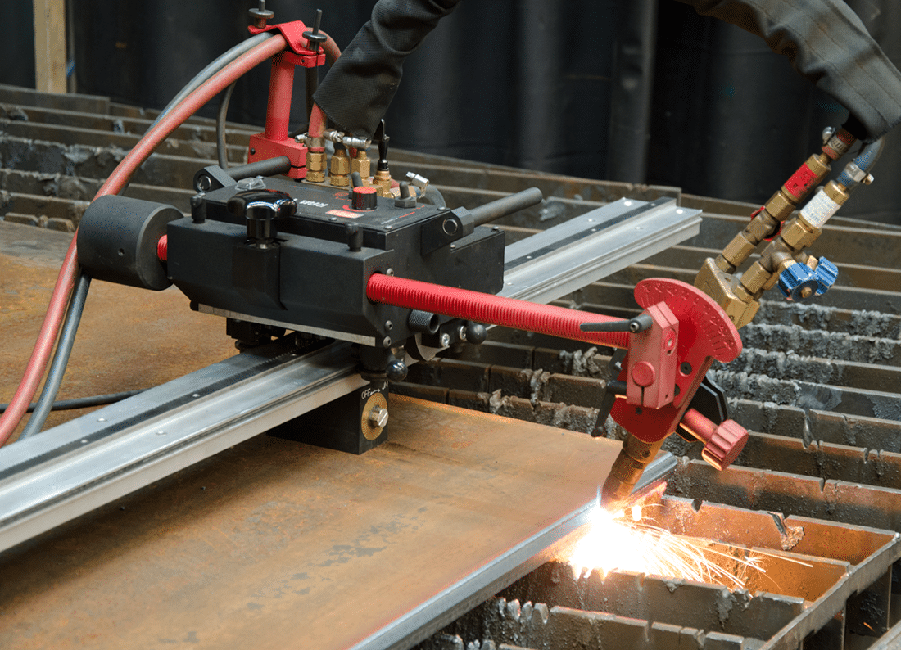

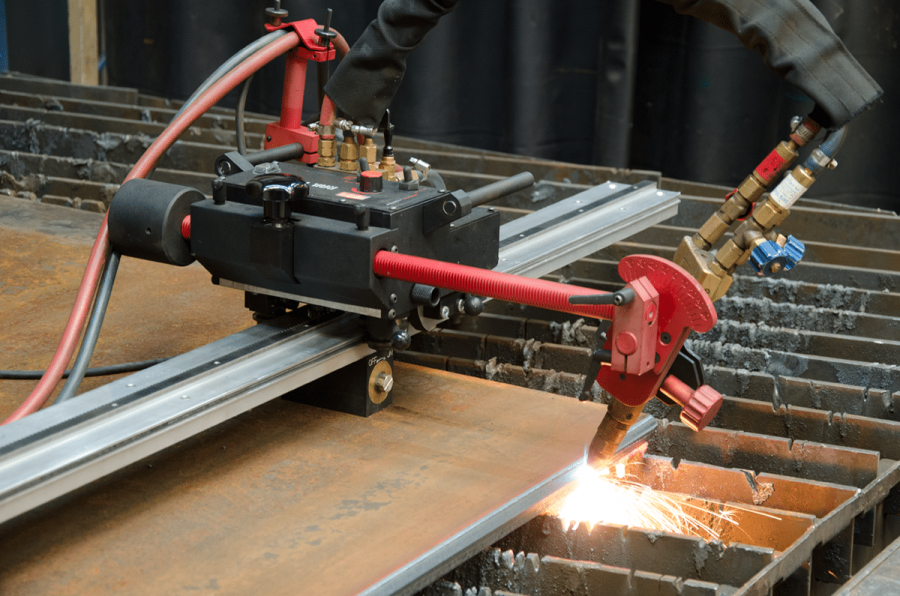

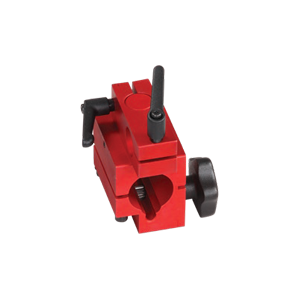

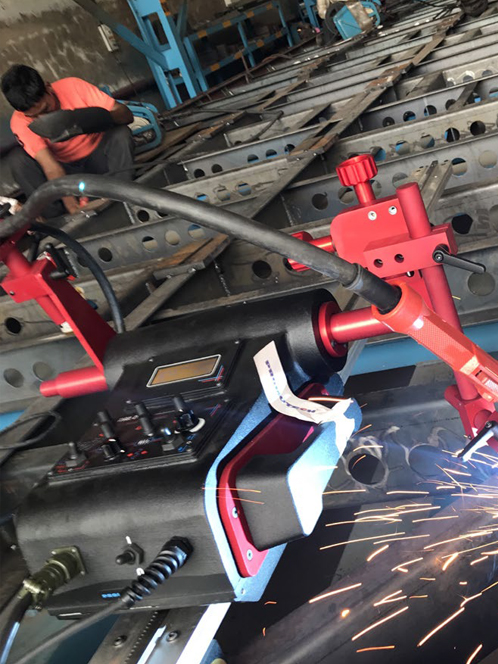

Rail Tug | Welding and Cutting Tractor

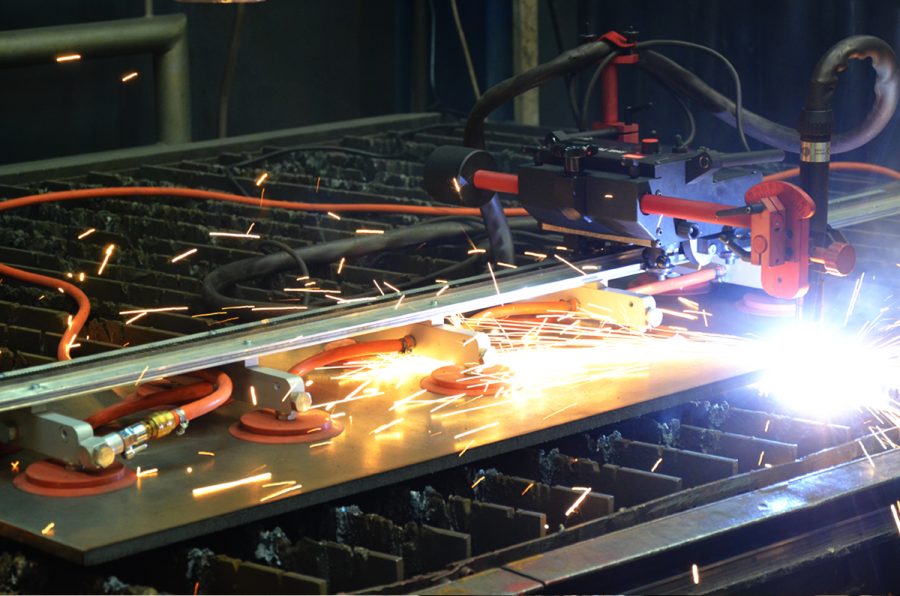

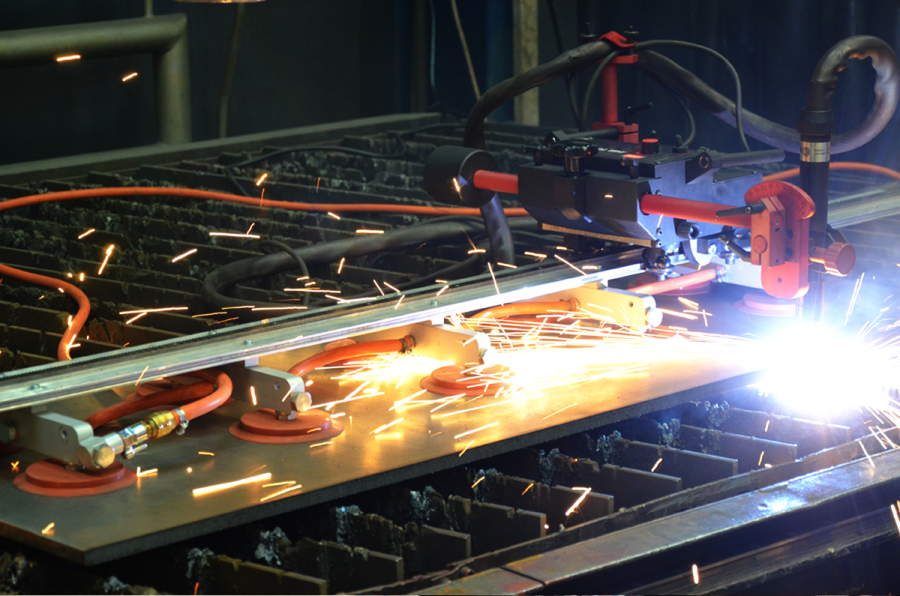

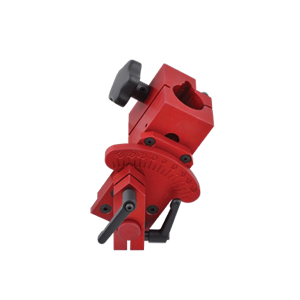

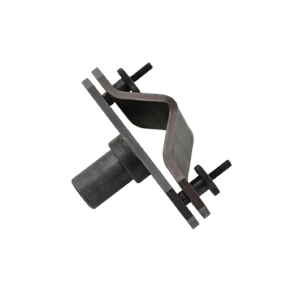

The Rail Tug is a basic tractor designed for the mechanization of welding and thermal cutting processes. The tractor can move along ring, hi-flex, semi-flexible or rigid tracks on flat, curved and round surfaces. The tracks can be fixed to both ferromagnetic and non-ferromagnetic materials thanks to various magnetic or vacuum units. Featuring a rack and pinion drive system with electronic speed control, Rail Tug creates weld bead geometry which is exact to your specifications, reducing costly over welding and decreasing filler metal usage.

The Rail Tug economically meets a broad array of welding and cutting applications on flat or curved plate, tube and pipe.

- Compact, lightweight design

- Closed loop speed control system stabilizes travel speed enabling uniform heat input to produce consistently high-quality welds and cuts

- Digital LED display for pre-setting travel speed

- Convenient power supply 115–230 V, 50–60 Hz

- Suitable for a variety of circumferential and irregular surface applications down to a minimum radius of 100 mm (4”)

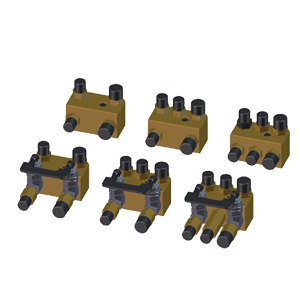

- Ring tracks on diameters from 200 mm (8”) OD up to 3 m (10 ft) OD

- Hi-Flex tracks on diameters from 1500 mm (59”) OD upwards

- Semi-flexible tracks can be bent to a minimum radius of 5 m (16 ft)

without permanent deformation