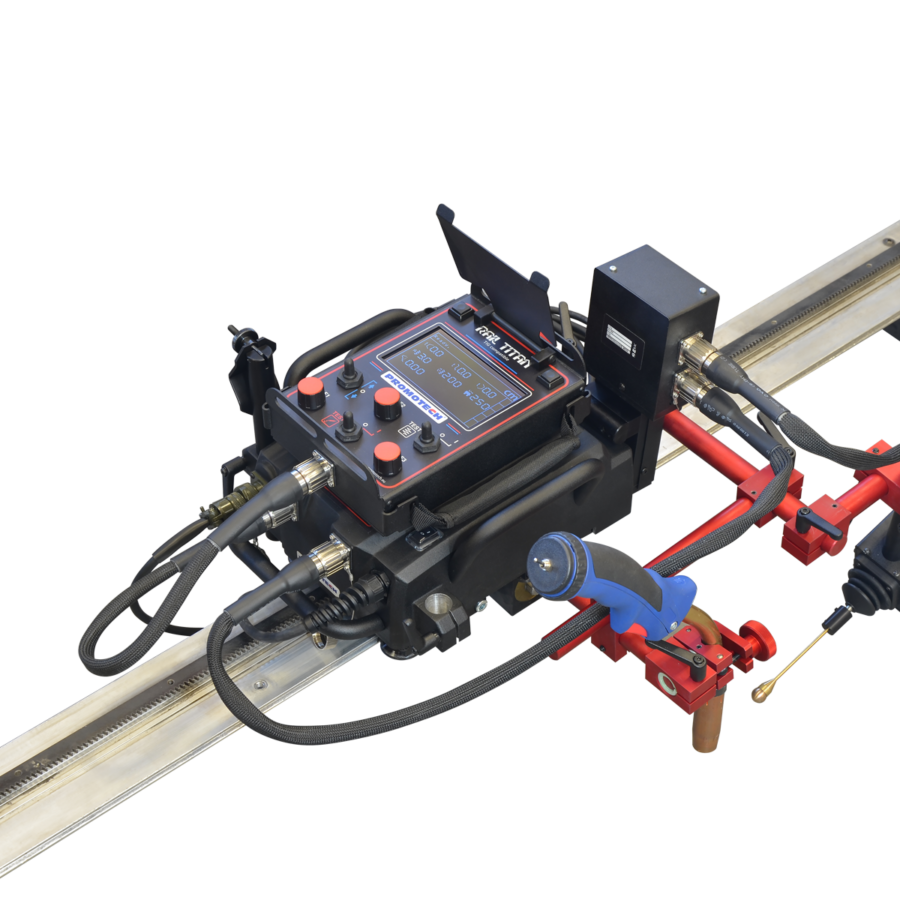

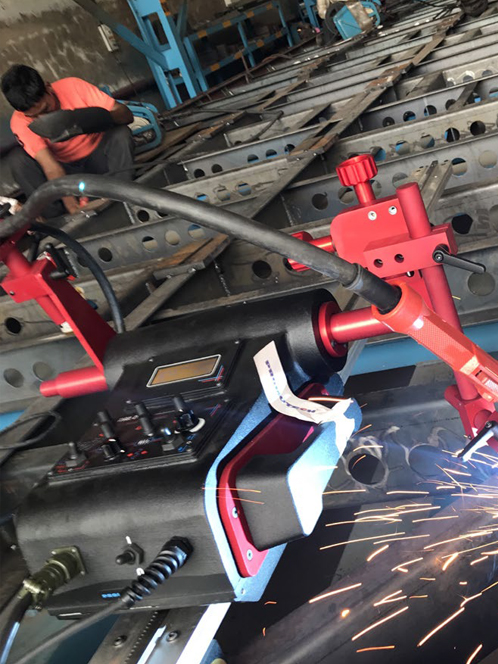

Rail Titan | Modular TIG-MIG-MAG Rail Tractor

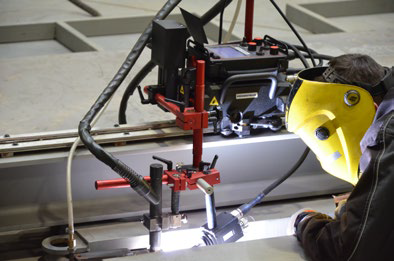

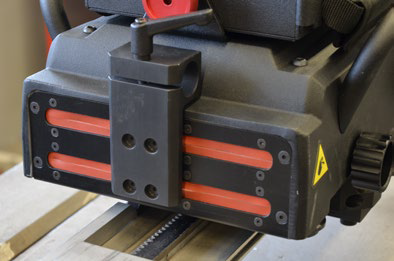

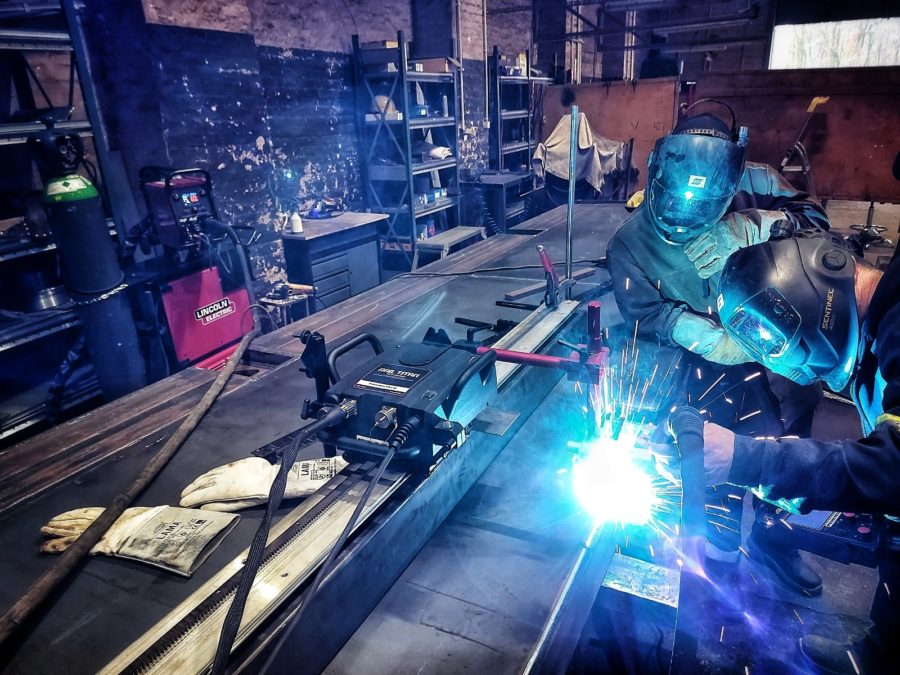

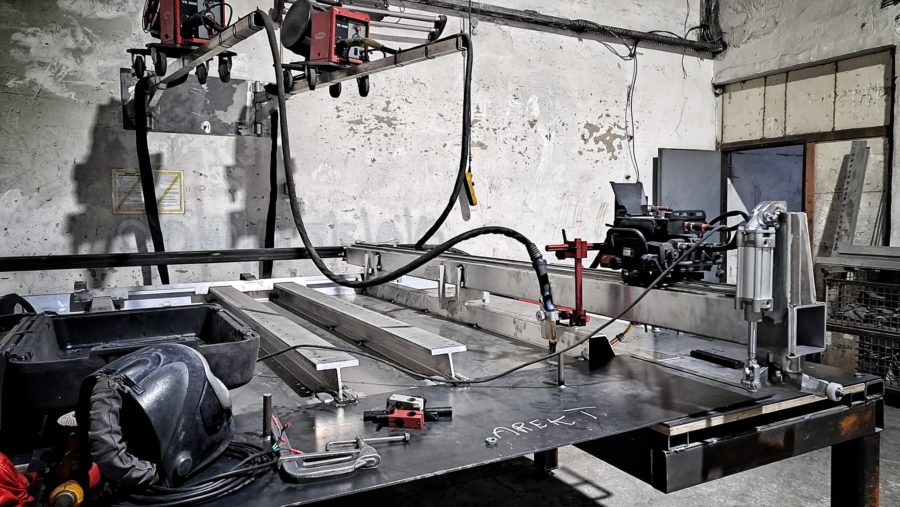

The Rail Titan is a fully modular mechanized tractor that can be custom configured for TIG-MIG-MAG welding, oxy-fuel, or plasma cutting and gouging applications on flat or curved plates, tubes and pipes. Linear torch oscillator produces straight, triangle, trapezoid, and square weld paths. The Rail Titan can travel on the ring, hi-flex, semi-flexible or rigid tracks that can be clamped to ferrous materials with magnetic units and to non-ferrous materials by means of a vacuum track system incl. vacuum pump, and vacuum units.

A digital display with a numeric representation for each motion parameter makes presetting the optimum welding or cutting procedure simple and highly repeatable. Optional accessories include tactile probe seam tracking and a motorized vertical torch slide for automatic torch height control.

- Suitable for TIG welding (HF resistant)

- Advanced closed-loop position control system based on the electric motor with a high-resolution encoder ensures increased accuracy of speed and positioning

- Ergonomic remote control pendant with simple and easy-to-find control knobs makes adjustments possible without lifting the operator’s welding hood

- Programmable path of stitch welds

- Suitable for a variety of circumferential and irregular surface applications down to a minimum radius of 100 mm (4″)

- Ring tracks on diameters from 200 mm (8″) OD up to 3 m (10 ft) OD

- Hi-Flex tracks on diameters from 1500 mm (59″) OD upwards

- Semi-flexible tracks can be bent to minimum radius of 5 m (16 ft) without permanent deformation

- Seam tracking enables active compensation of torch position vertically and horizontally with and without oscillation

- Suitable for all welding positions on both ferromagnetic and non-ferromagnetic materials