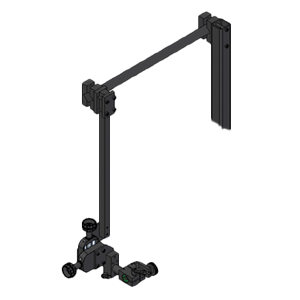

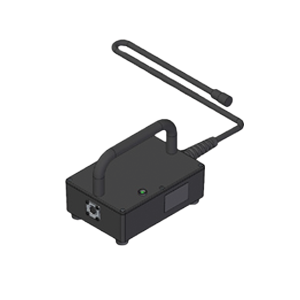

PRO-WP 150 Welding Positioner

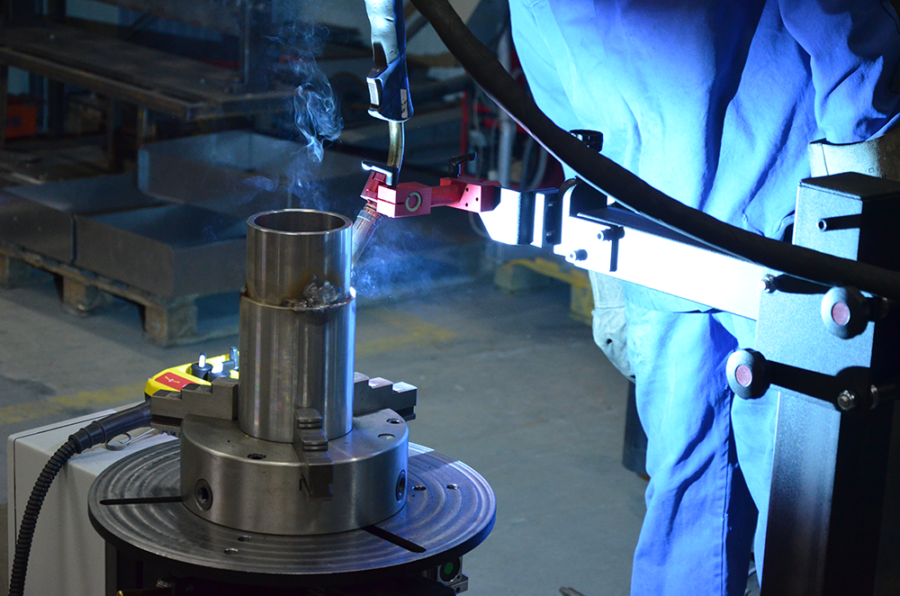

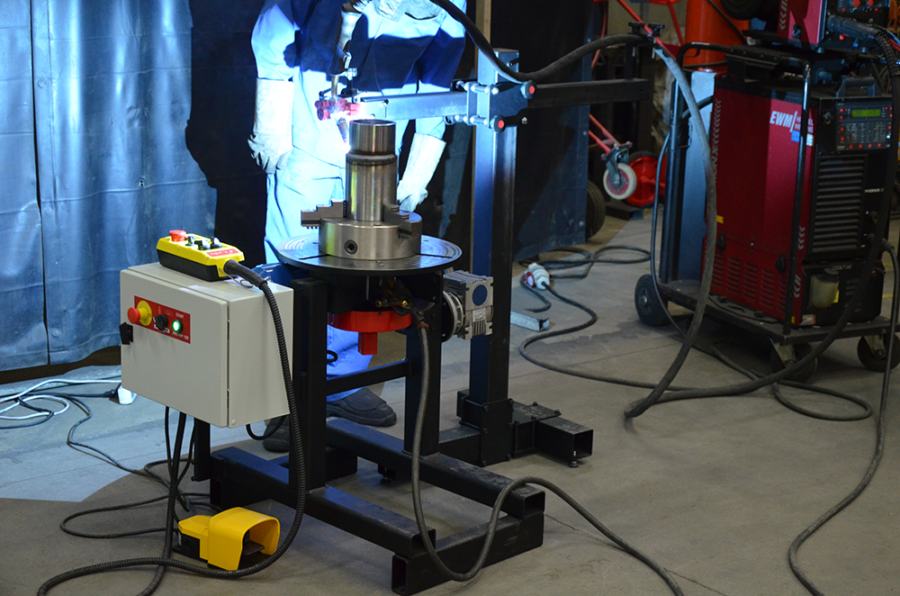

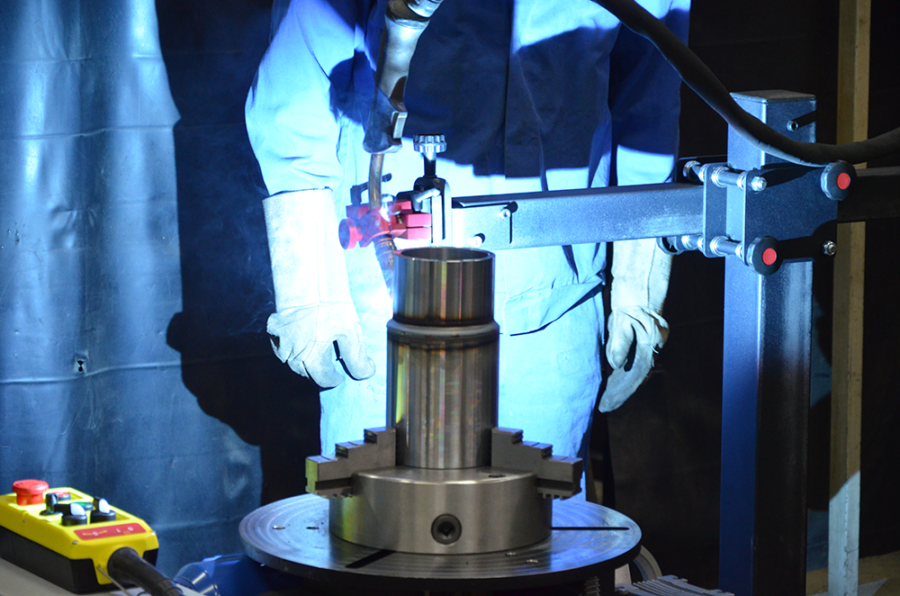

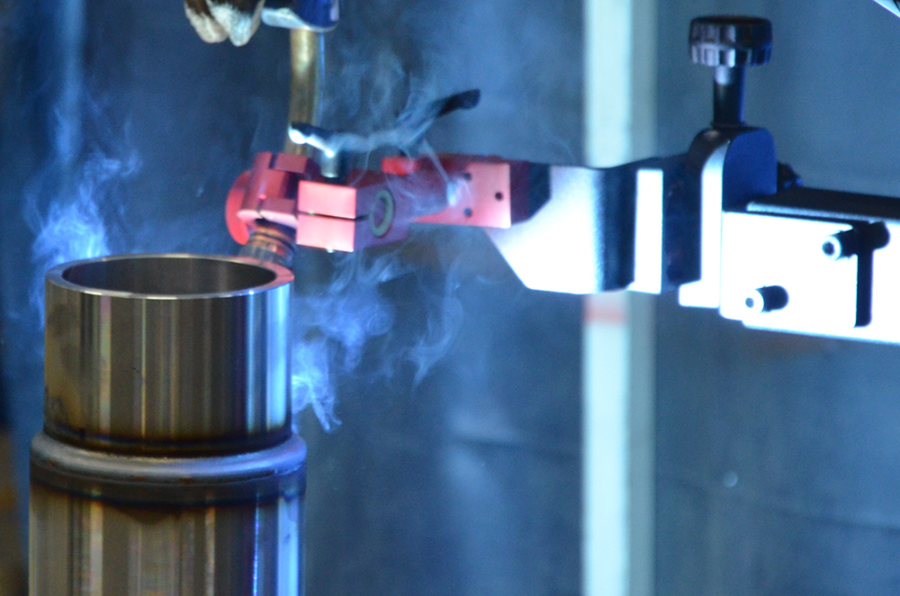

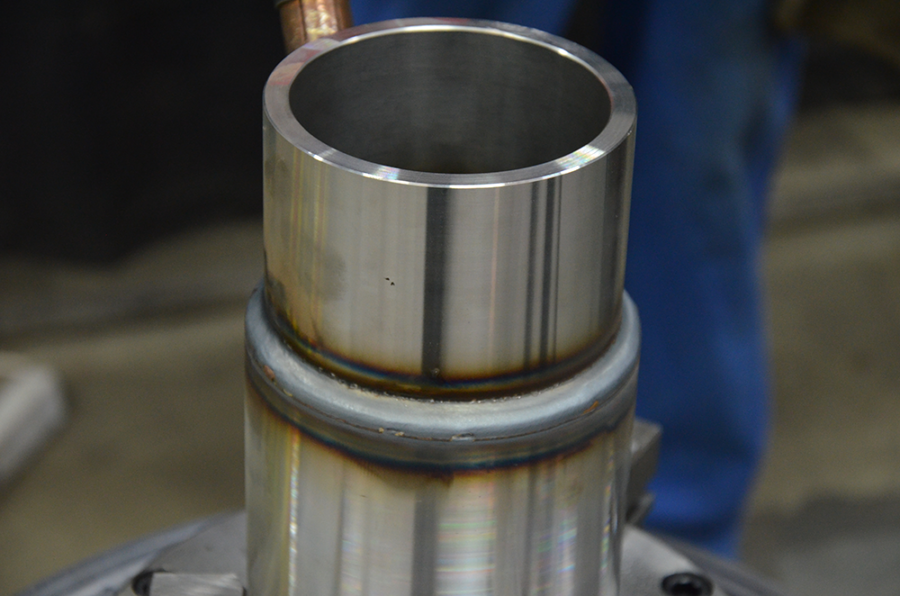

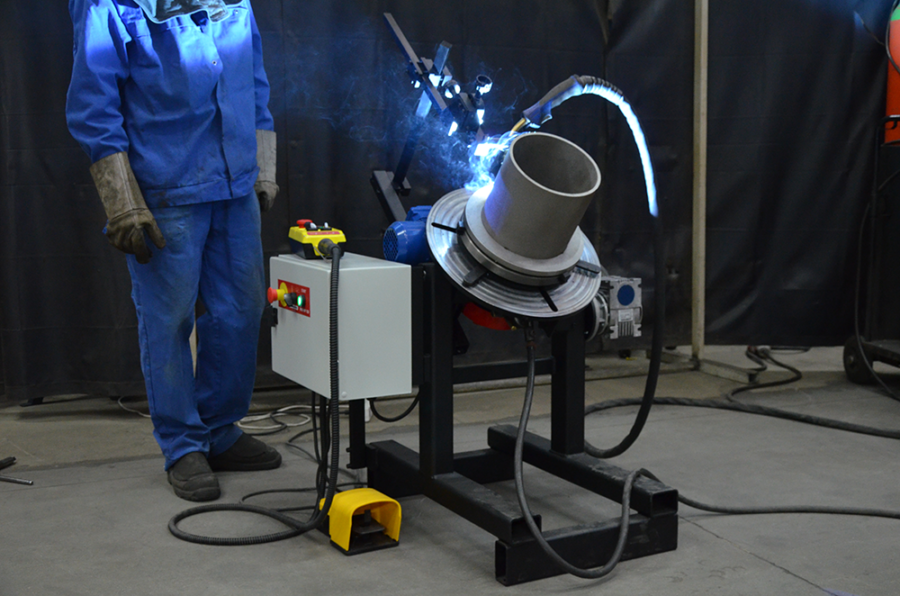

The frequency inverter ensures continuous speed adjustment and speed stabilization at the set value. They reduce time and effort for the welders, who can focus on their job with no need to constantly move around their workspace in order to get the best position. The compact design takes up minimal floor space and tilting up to 90 degrees improves the ergonomics of the workspace. The selection of various auxiliary accessories makes it possible to create an advanced modular welding station and customize it depending on required welding or cutting applications to maximize production efficiency.

- Left or right rotation

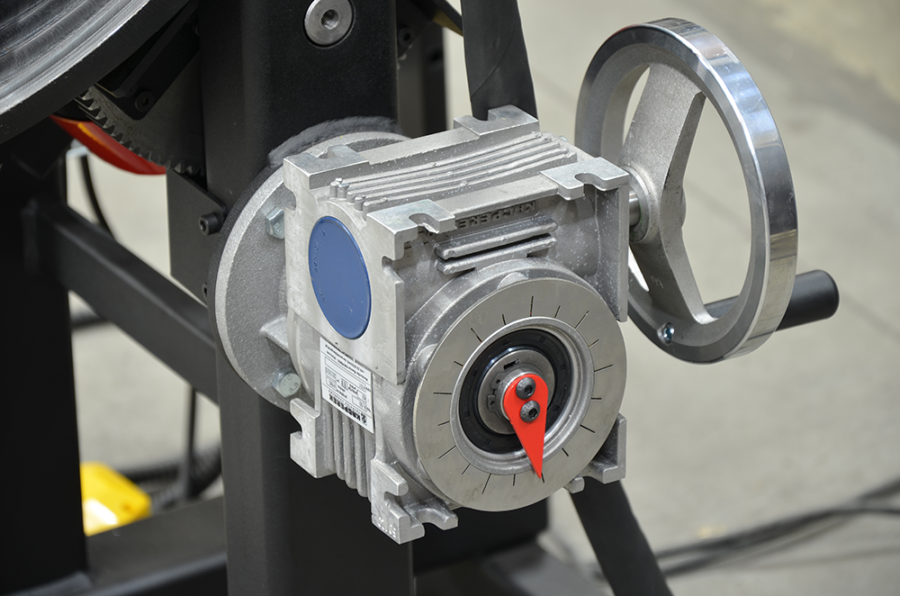

- Continuous speed adjustment

- Speed stabilization within full speed range from 0,12 rpm up to 2,4 rpm

- Start/Stop (both controller and foot pedal)

- Arc ignition

- Remote control

- Foot pedal for hands-free operation

- Heavy-duty construction

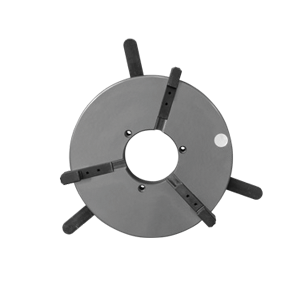

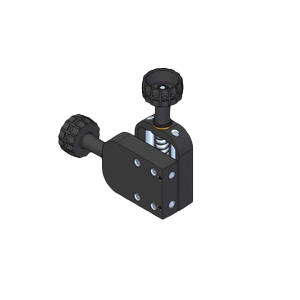

- Lots of auxiliary accessories enable the building of a modular welding station tailored for various welding and cutting applications