Gecko Battery | Battery Powered Welding Carriage

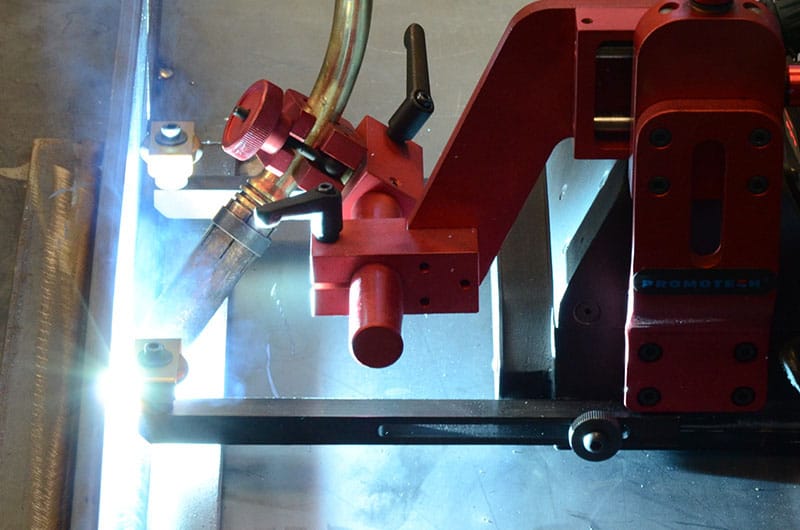

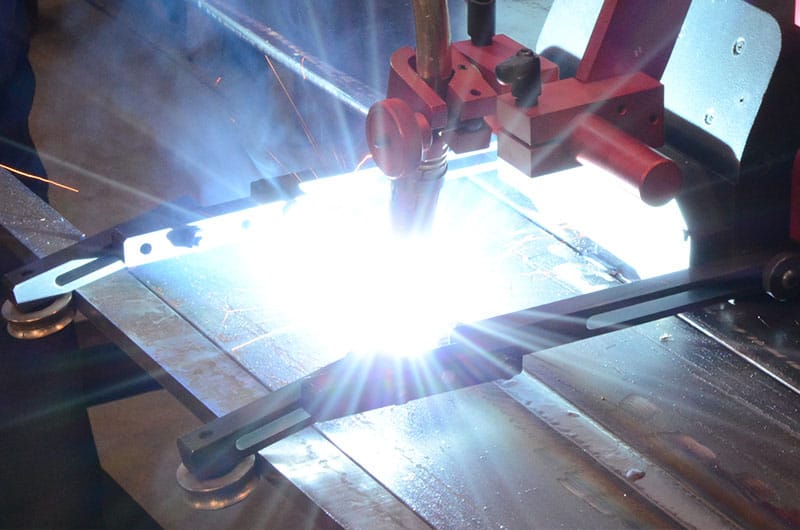

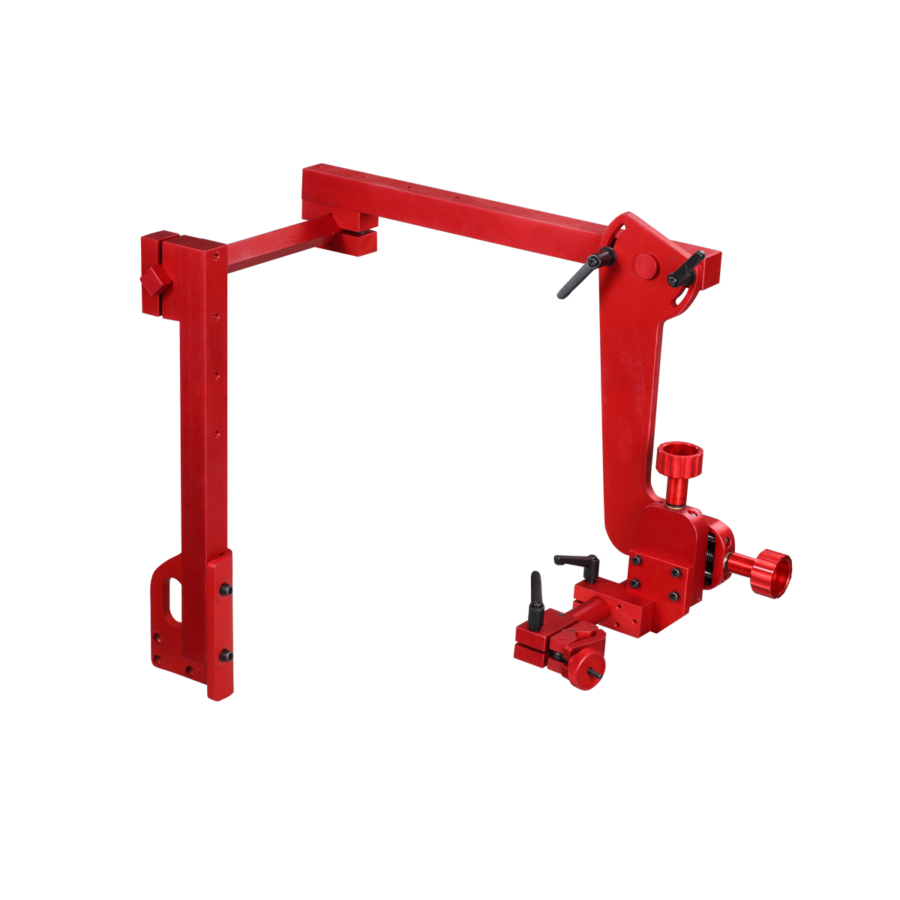

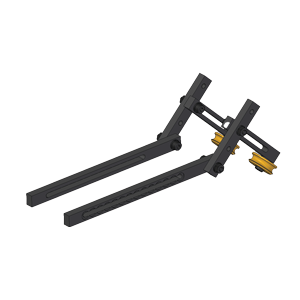

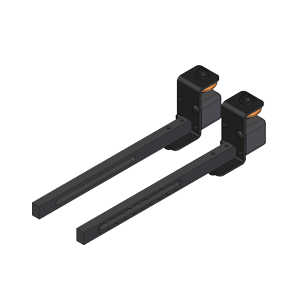

The GECKO BATTERY is a battery-powered trackless welding tractor designed to produce continuous butt and fillet welds using MIG/MAG torches. CAS LiHD battery delivers enough power for handling even the toughest applications with no cables. A 4-wheel drive system with magnetic traction and a feedback loop provide speed stabilization in various welding positions. Constant, continuous, and repeatable travel speed enables weld bead geometry that is exact to the required specifications, thus reducing costly over welding and substantially decreasing filler metal usage.

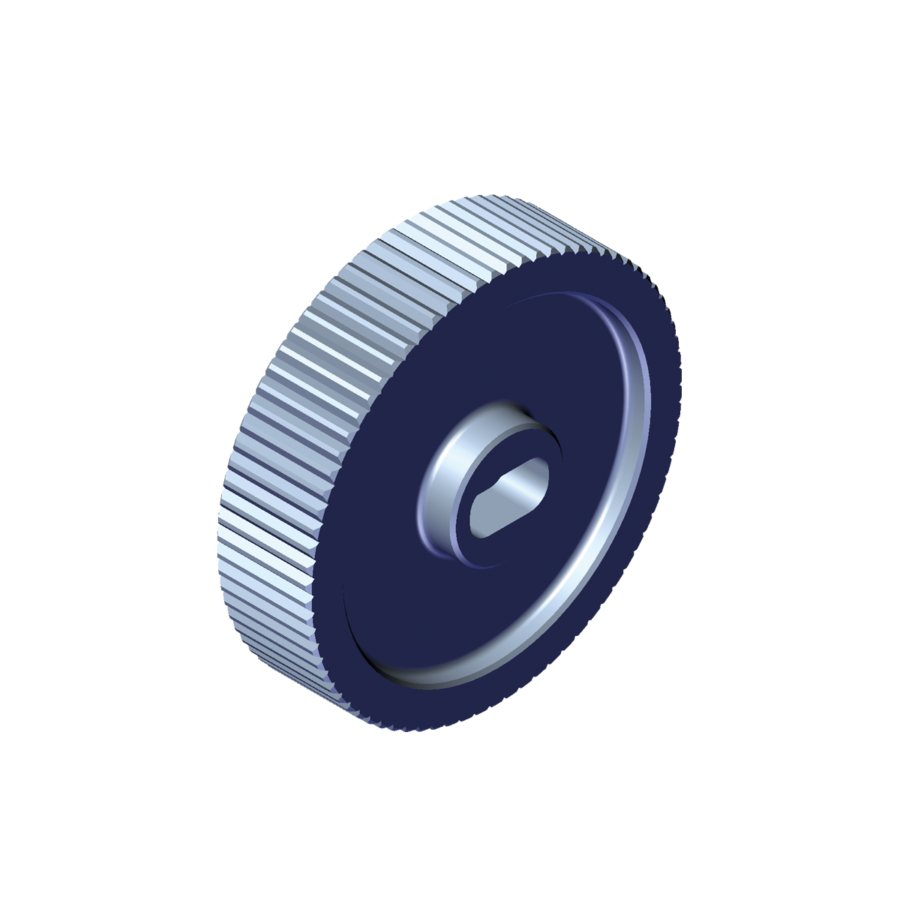

- Convenient 18 V DC battery supply (the same battery for both Mini Spider and Gecko Battery)

- LiHD battery ensures maximum power availability for an extremely long time

- Intelligent battery management for long-lasting battery

- Digital speed control and stabilization for high quality welds

- Multifunctional LED display to present travel speed, units and diagnostic messages

- Compact, lightweight design with durable aluminum cast housing

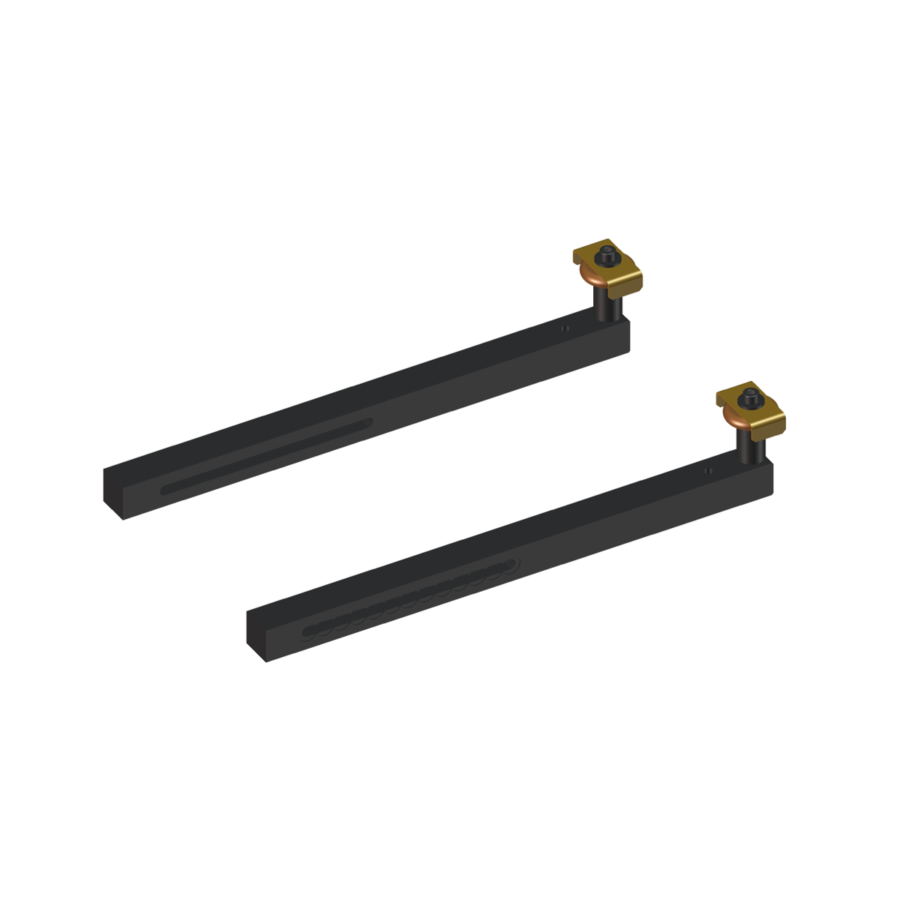

- Optional accessories make Gecko Battery fit for various applications with carbon steel, stainless steel and aluminum