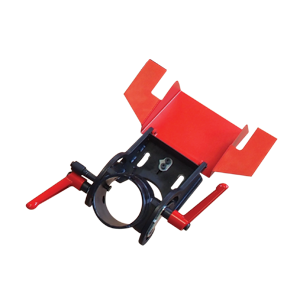

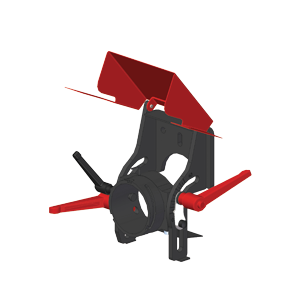

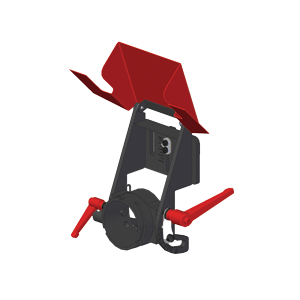

ABM-28 | Auto Feed Plate Beveler

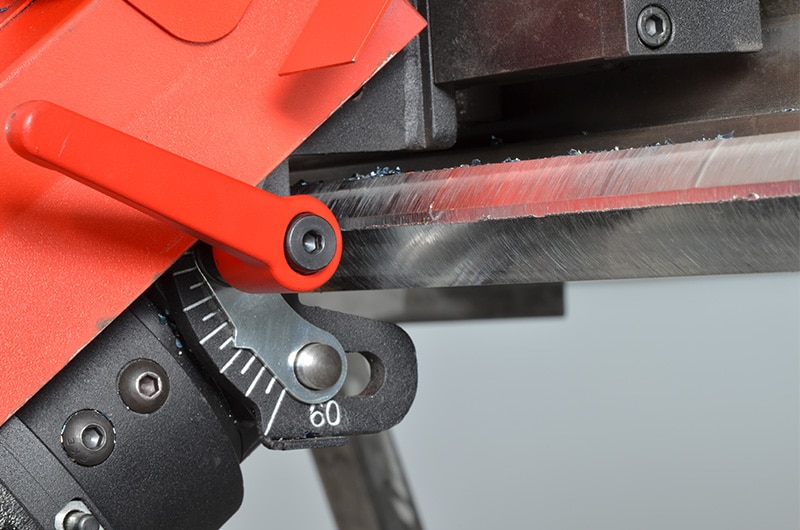

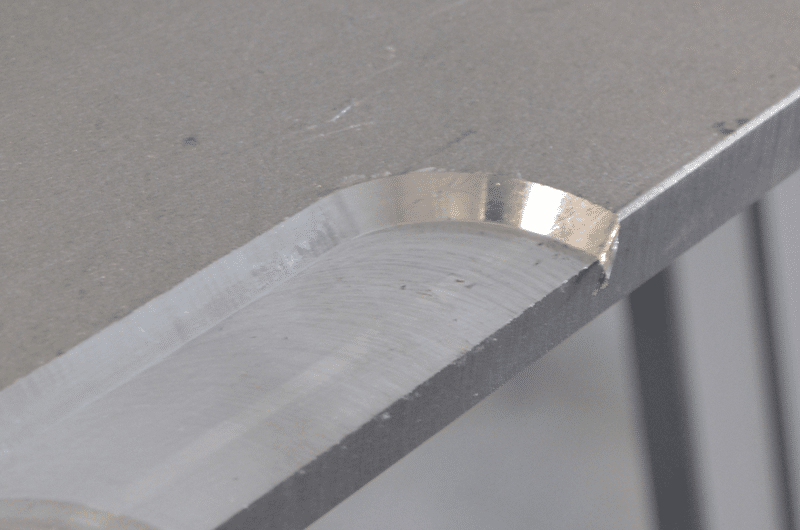

ABM-28 self-propelled machine produces accurate high-quality double-sided bevels without thermal distortion or creation of heat affected zone. The machine can work in both travel directions, eliminating the hard physical work of the operator. ABM-28 features an infinitely adjustable bevel angle between – 60 and + 60 and is capable of producing bevels up to 28 mm wide.

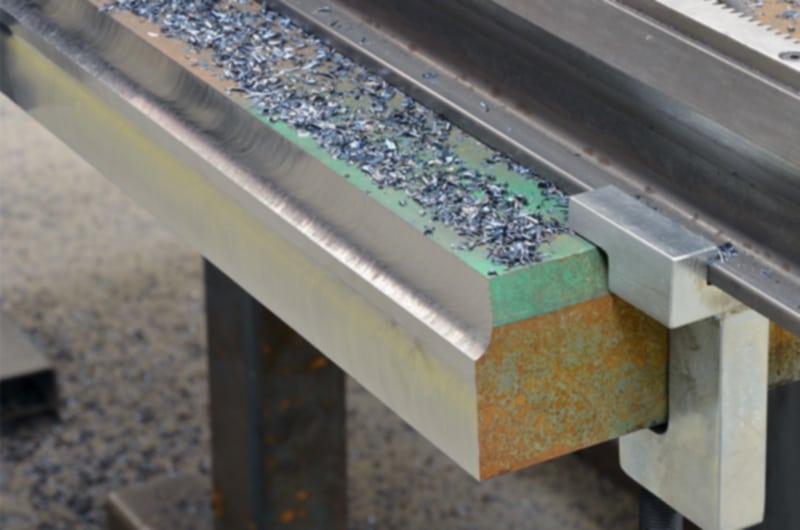

- Auto feed beveling on steel plates on top, face, and bottom edges

- The continuously adjustable bevel angle between 60 and minus 60 degrees – no need to rotate or flip heavy material, enhancing safety and reducing material handling time and expense

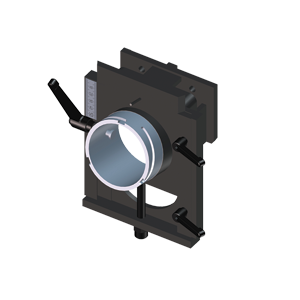

- Max. bevel width from 28 up to 35 mm depending on the beveled angle

- Variable feed control for work on a variety of steel grades and thicknesses up to 35 mm as standard or optionally up to 70 mm thickness

- Motor overload protection to prevent motor damage

- Additional guide tracks are joinable to accomplish the required run length

- J-groove beveling available as an option