How to create j-groove weld preparation on plates and pipes?

The process of j-groove weld preparation requires high accuracy provided by dedicated solutions. Special pipe and plate bevellers creates surface with the highest quality standards.

What is j-groove bevelling?

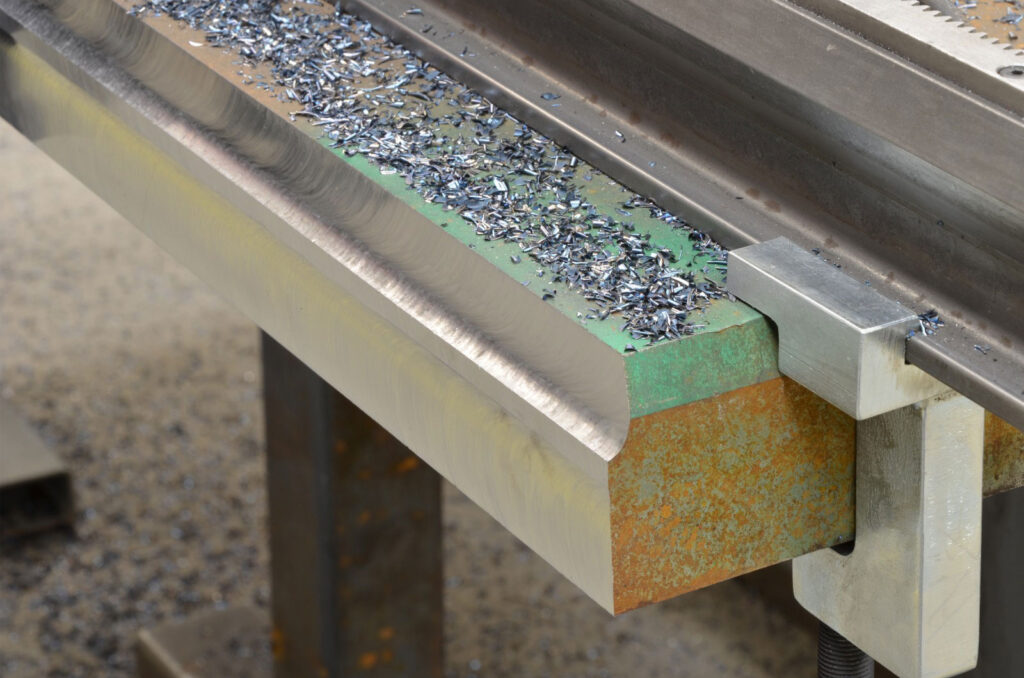

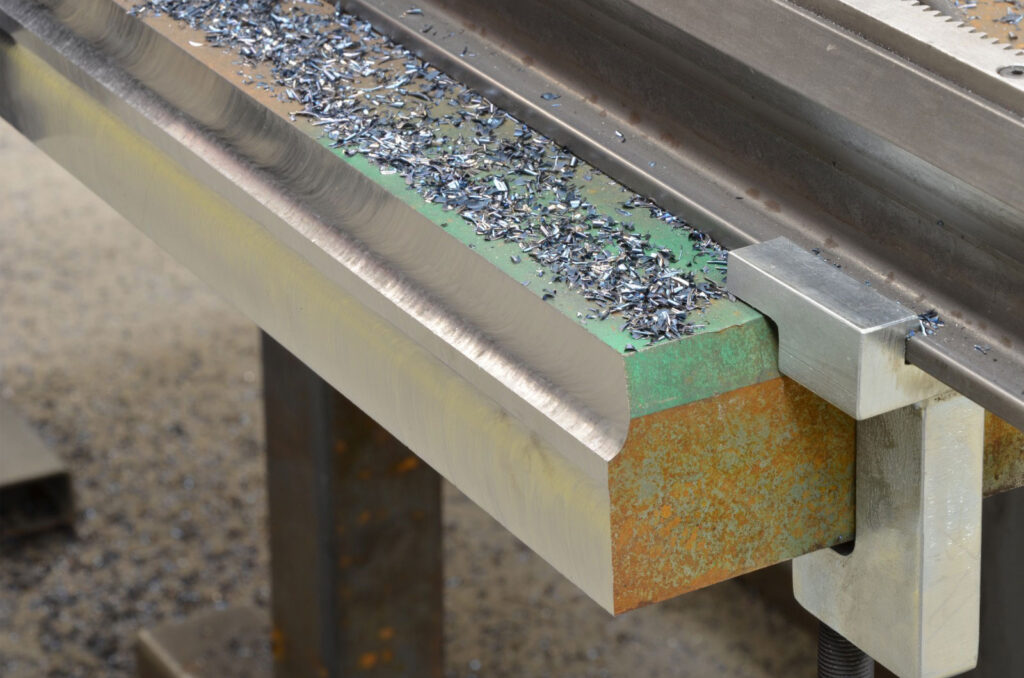

Welding surface preparation is common welding practice that ensures the strongest possible weld. J-bevelling is the base for many types of welding joints (such as single-J, double-J, single-U and double-U). This type of bevel is mostly used on the end of the tubing, pipe, and boiler, but it’s also suitable for heavy metal walls.

Why j-groove bevel?

The most important aspect of J-weld prep is that it drastically reduces the volume of the bevel. So it means that J-groove weld requires a relatively low amount of consumables and less time to weld the joint. This is why J-bevel is the best solution for thick surface weld preparation. But there’s also the disadvantage of the J-groove – it’s difficult to do by hand. It’s not only about fatigue, but it’s difficult to keep a uniform J pattern manually. So, the application of even and quality J-bevelled surface requires a bevelling machine. Especially if it’s about a significant number of workpieces.

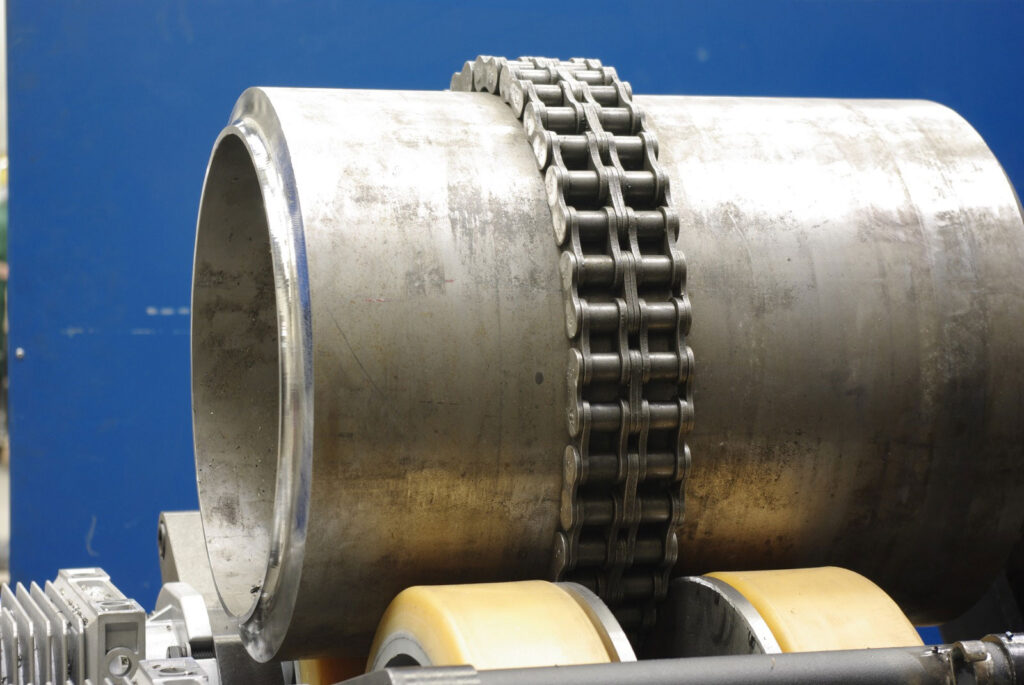

Portable pipe bevelling machines are an irreplaceable solution if it comes to small pipes and tubes. Thanks to the self-centering expandable mandrel, the beveller always perfectly aligns to pipe or tube. Wide range of replaceable tool bits enables J-groove bevelling as well as OD bevelling, ID bevelling and facing–off applications. It is essential to achieve the highest quality of weld, such that the weld is as good as the parent metal. A well-chosen J-groove beveller is the certain investment that lays the foundation for high-quality welds through accurate bevelling with no heat-affected zones or distortion.

Portable pipe bevelling machines are an irreplaceable solution if it comes to small pipes and tubes. Thanks to the self-centering expandable mandrel, beveller always perfectly aligns to pipe or tube. Wide range of replaceable tool bits enables J-groove bevelling as well as OD bevelling, ID bevelling and facing–off applications.