Different kinds of drilled metals:

Specialty metals and special-purpose alloys are present in many industries on a daily basis. They are often used because of desirable properties such as hardness (e.g. hardox, duplex), low weight (e.g. aluminum), higher conductivity (e.g. copper), non-magnetic property or resistance to corrosion (e.g. stainless steel, zinc). But the most commonly used is stainless steel. From the little button to the largest skyscraper, stainless steel is an essential part of our times.

The best method for drilling stainless steel

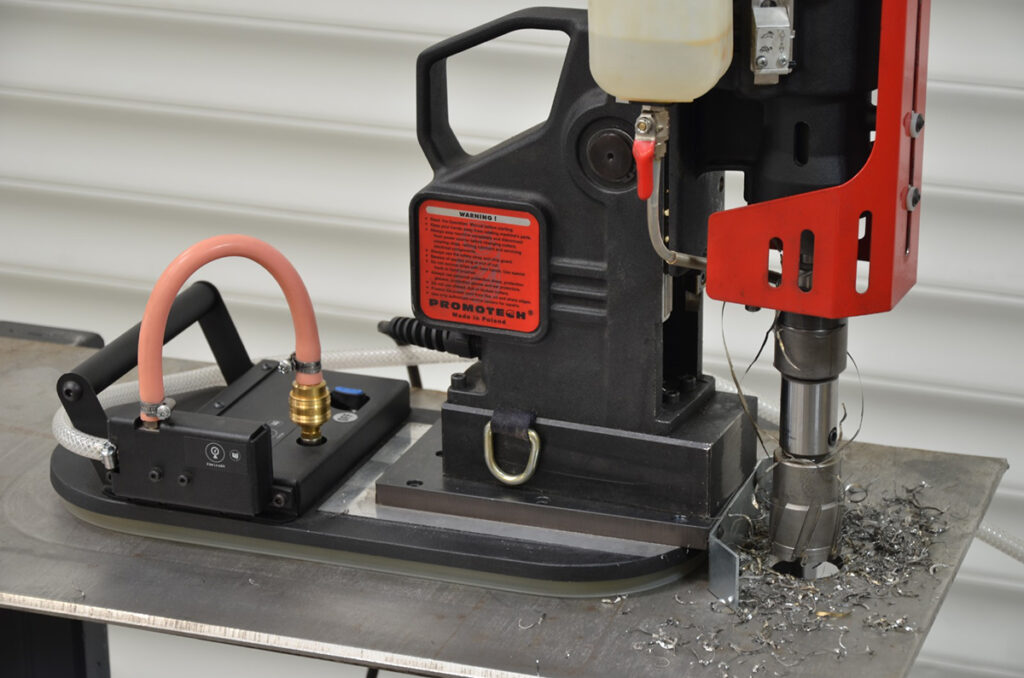

For this moment, the most effective method for making holes in steel is to use mag drill equipped with Tungsten Carbide Tipped annular cutters. Thanks to multiple cutting teeth that cut only the periphery of the hole, it’s removed a small amount of material around the edge of the hole (whereas twist drills convert the entire hole to a chip). TCT works fine, especially for drilling holes over 14 mm in diameter. However, HSS bits are also suitable for making holes over 12 mm of diameter, but for smaller holes twist drill bits work better.

The most effective method for drilling holes in stainless steel requires proper drill bits and also a magnetic drilling machine. And it’s obvious that, in order to launch a mag drill, it’s required to mount an electromagnetic base on the surface. So, how to apply this method when it comes to drilling non-magnetic metals like stainless steel or aluminum?

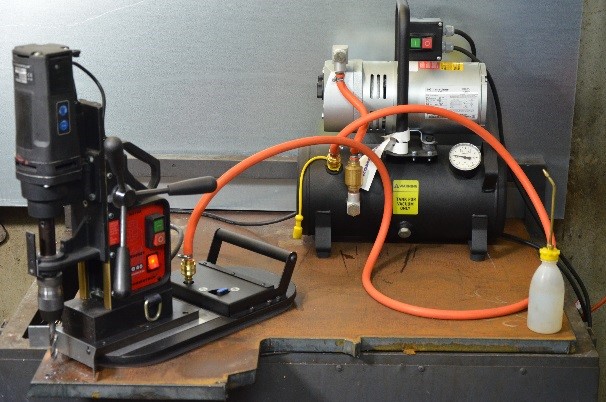

Mounting mag drill to a non-magnetic surface

Fortunately, there is a smart trick that allows using mag drill on the surface which doesn’t react with the magnet. Mag drill producers offer Vacuum Pad – clamping devices enabling ability to drill on non-magnetic or thin surfaces. Pad is powered by a compressed air supply, available in most production/manufacturing sites. In the case of lack of compressed air supply, there’s the possibility to supply a vacuum pad by vacuum supply. In this case, the only requirement is 115V or 230V of power supply for the vacuum pump. A simple solution that opens the possibility to use a mag drill for inox, hardox, duplex, or aluminum.

Three golden rules of drilling stainless steel

Summing up the topic, the right method can make a real difference in how smoothly the operation goes. To systematize knowledge before drilling stainless steel it’s worth remembering three important tips:

1. Proper drill bit for stainless steel

The best drill bit to drill hardened steel is Tungsten Carbide Tipped hole saw cutter. Thanks to their properties they can easily cut through stainless steel without damaging the surface. Sintered and finished carbide has a combination of compressive strength, extreme hot hardness at high temperatures, and resistance to abrasion, corrosion, and thermal shock. These are important factors in drilling hard materials because the friction of metal against metal can produce high temperatures. That damage the material or the drill bit.

2. Set the right rpm and keep an eye on the chips

If there is a possibility to set the rpm’s for stainless is usually about 50% less than mild steel. The trick is to use slow rpm and more feed pressure than is used with steel. An annoying, high squealing sound means that the rpm is too fast. Keep an eye on chips. When they are gold or blue, the drilling machine is running too fast. Drill swarf should come off in long spirals, not small chips.

3. Remember about coolant

Coolant is used to keep the cutter cool. During drilling through stainless steel heat is absorbed into hole cutters. Due to generated extreme heat, cutters quickly become dull or softened. It’s recommended to place a few drops of cutting oil on the surface of the stainless steel before beginning to drill. Periodically add more oil drops, until you have drilled completely through the stainless steel.