Rail Bull | Welding & Cutting Track Carriage

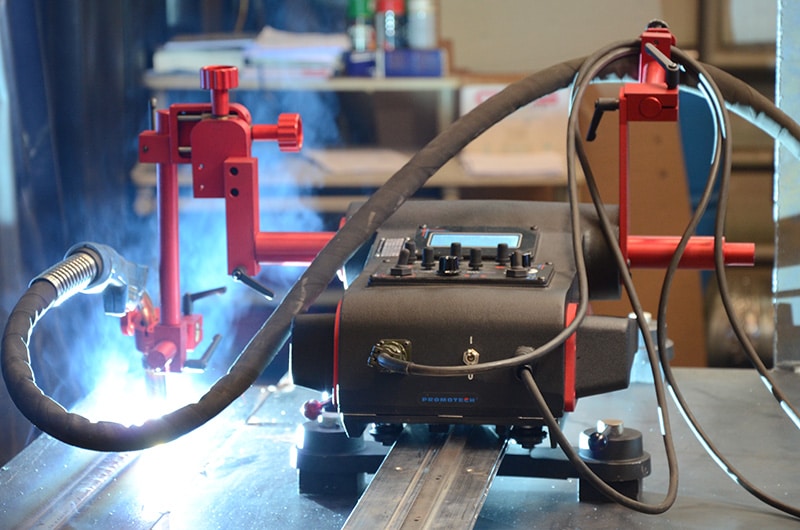

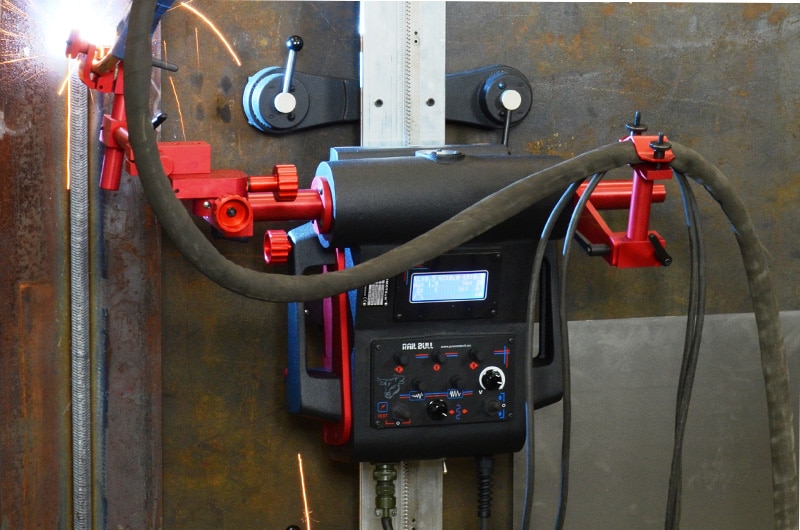

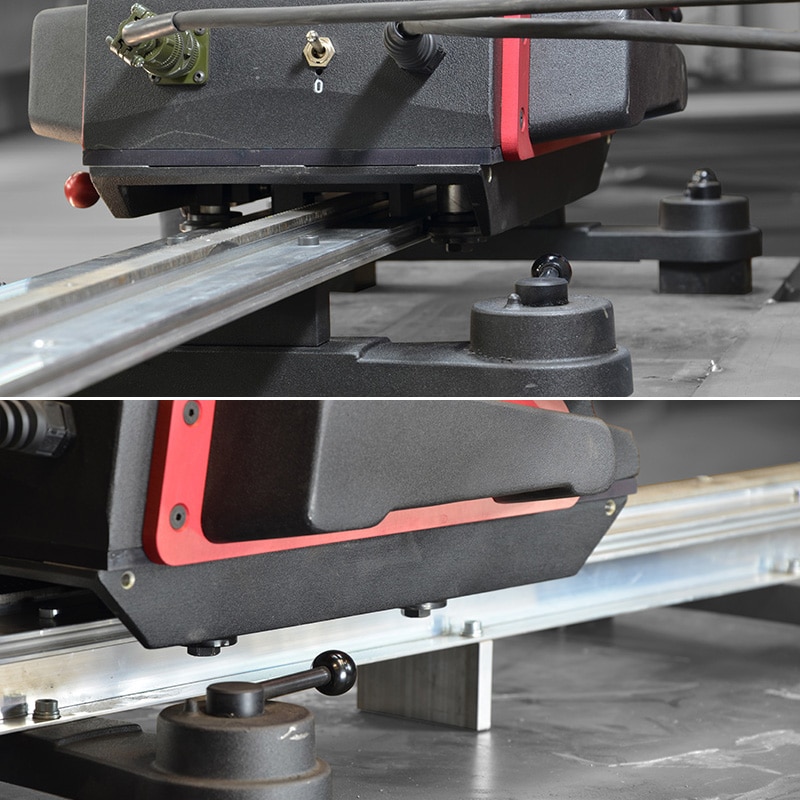

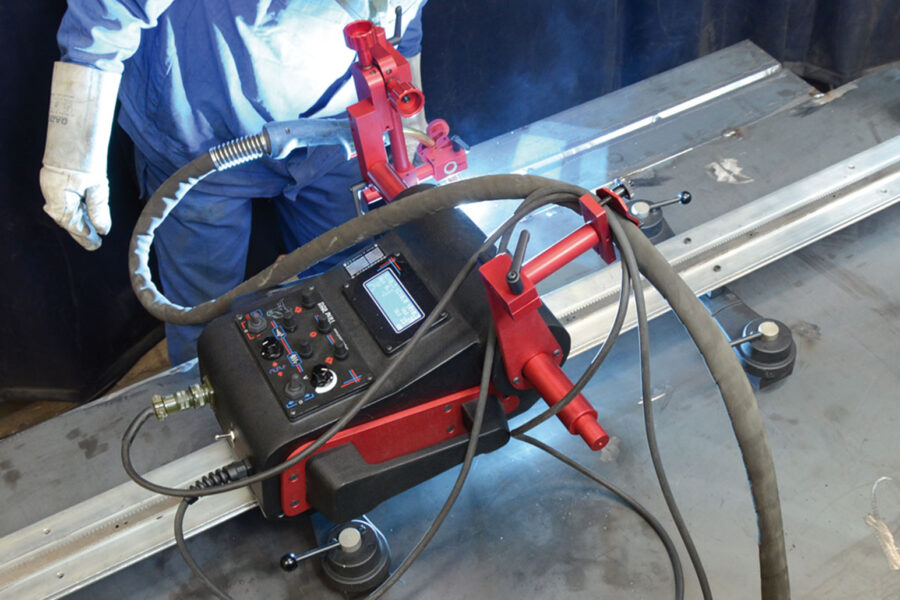

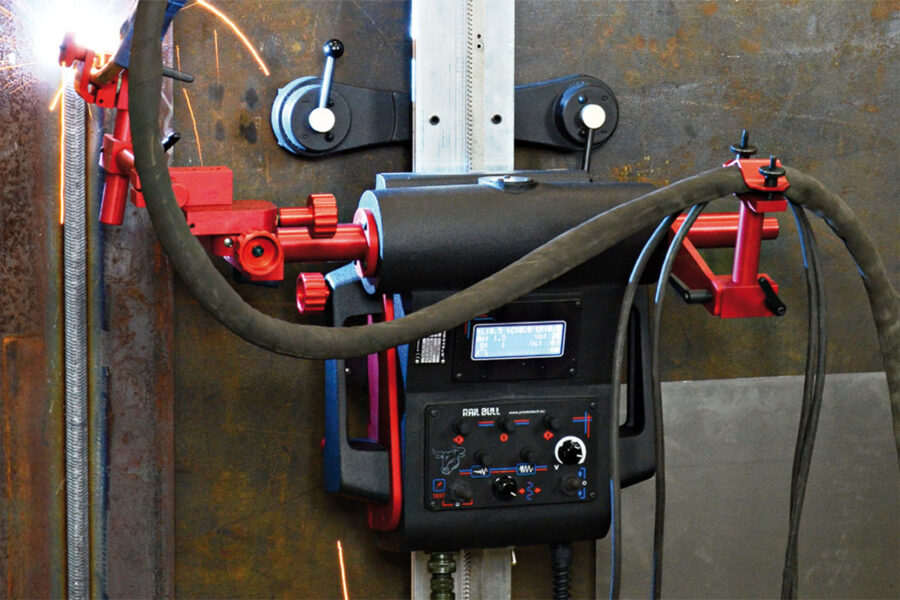

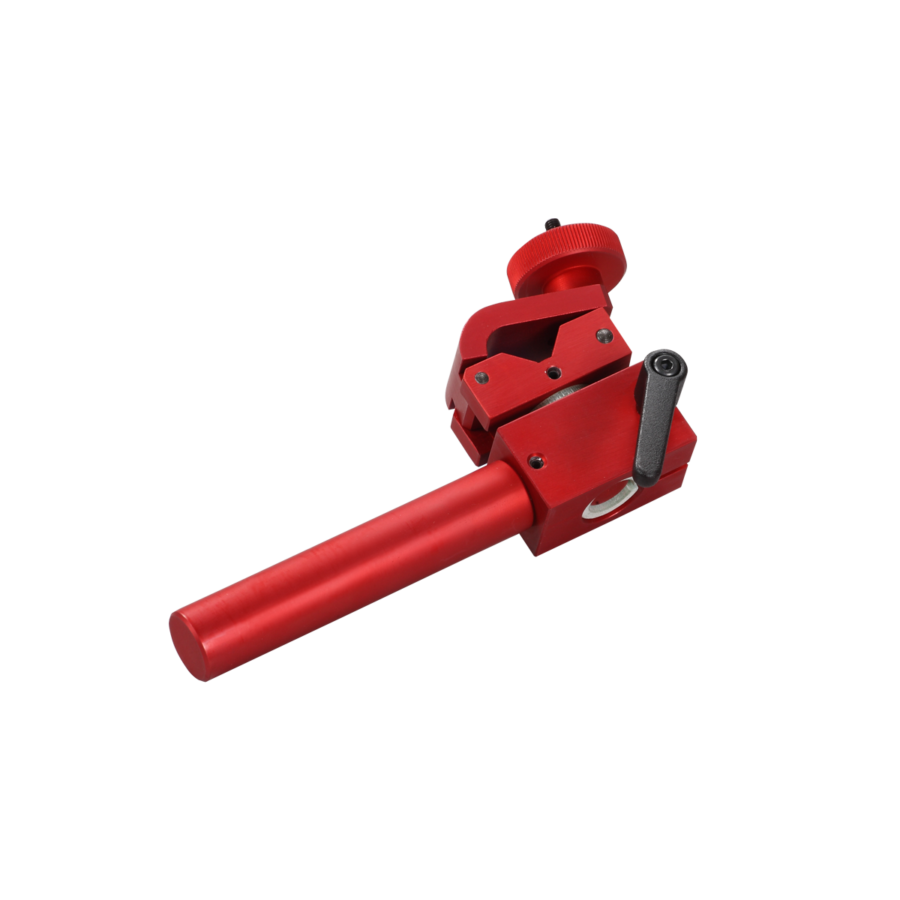

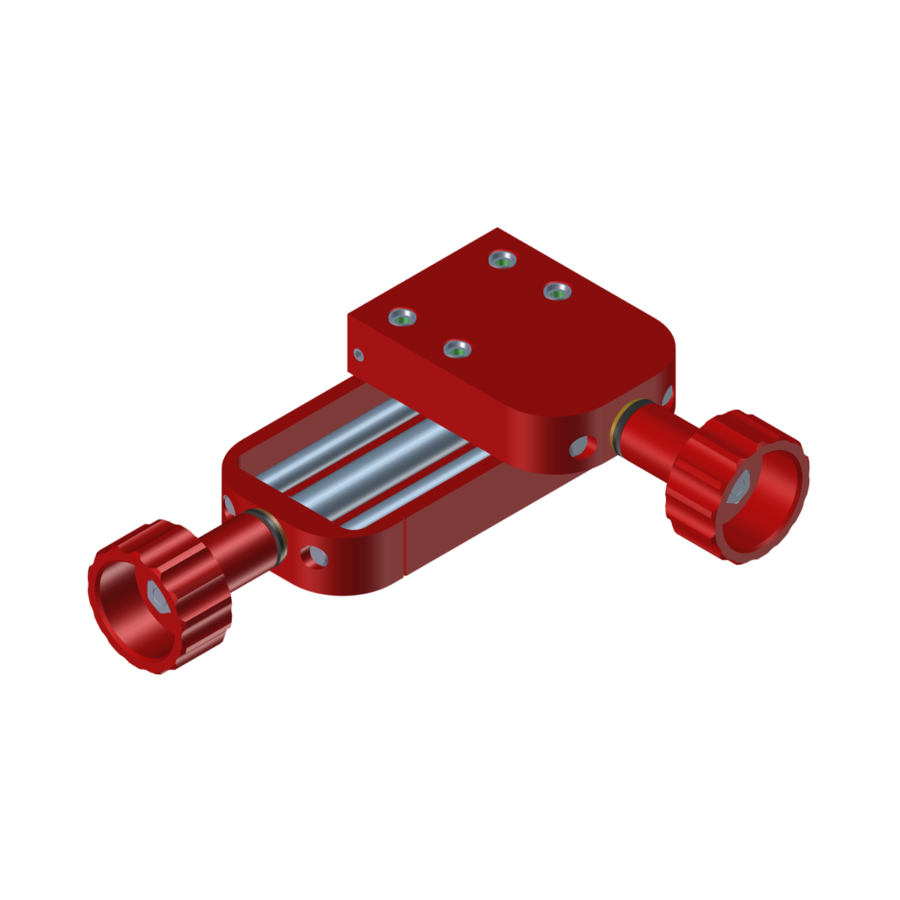

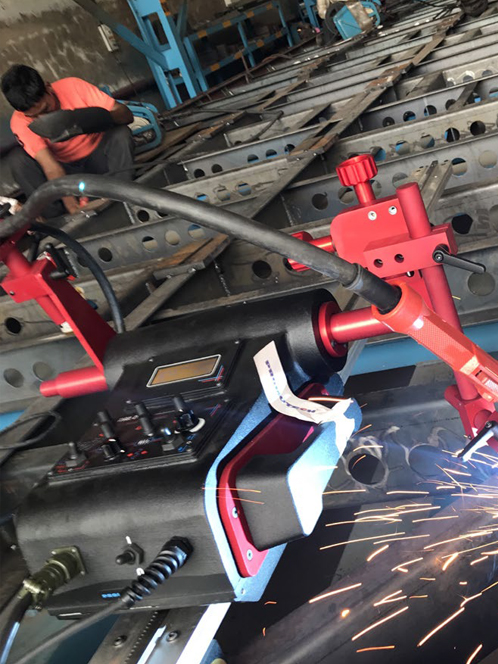

The Rail Bull is a digitally controlled welding tractor with an integrated linear oscillator. The tractor can move along rigid or semi-flexible tracks on flat and curved surfaces. The tracks can be clamped to ferrous materials with magnetic units and to non-ferrous materials by means of a vacuum track system incl. vacuum pump and vacuum units.

Featuring a rack and pinion drive system with electronic speed control, the Rail Bull can produce consistent, high-quality welds in flat, vertical, or horizontal positions.

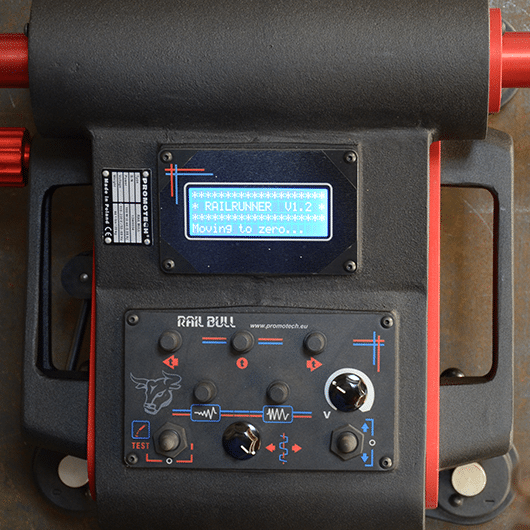

- Closed loop position control system based on an electric motor with an encoder ensures increased accuracy of speed and positioning

- Integrated linear oscillator for weave welding and overlay

- Multifunctional LCD shows process parameters and warnings

- Compact, lightweight design with a durable aluminum cast housing

- Convenient power supply 115–230 V, 50–60 Hz or 42 V, 50–60 Hz

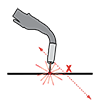

- Rail Bull produces consistently high-quality welds and cuts in a fraction of the time required by manual operations